Are you finding manual folding inefficient and inconsistent? SMH folding machines provide an efficient, smart solution!

In today’s digital marketing age, well-designed brochures, product manuals, and invitations remain vital for brands to connect with customers and showcase quality. However, manual folding is slow and error-prone, while outsourcing is expensive and delays projects. Is there a simple way to achieve professional, efficient folding in-house?

Why Your Business Needs a Folding Machine

Take full control, cut costs, and boost efficiency.

Handle everything from design to finished product independently. Whether it’s small personalized batches or materials for recurring events, you can quickly meet demand without relying on outside vendors—saving time, reducing communication hassles, and increasing profit margins.

Consistent Quality That Reflects Professionalism

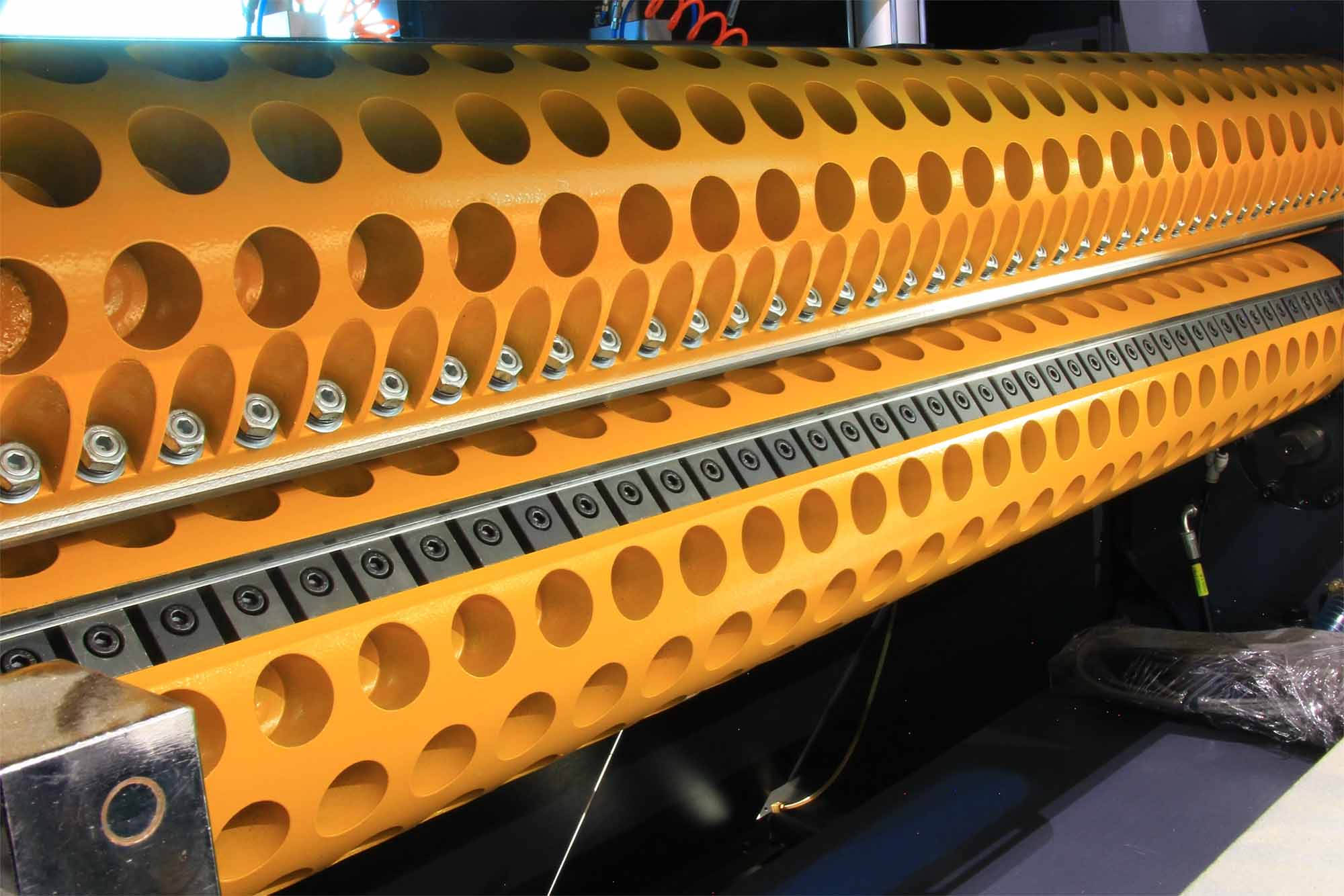

Hand folding often results in uneven creases, harming the appearance. Folding machines use precise mechanical or CNC technology to produce sharp, uniform folds every time—perfectly preserving your design and delivering professional results that impress your customers.

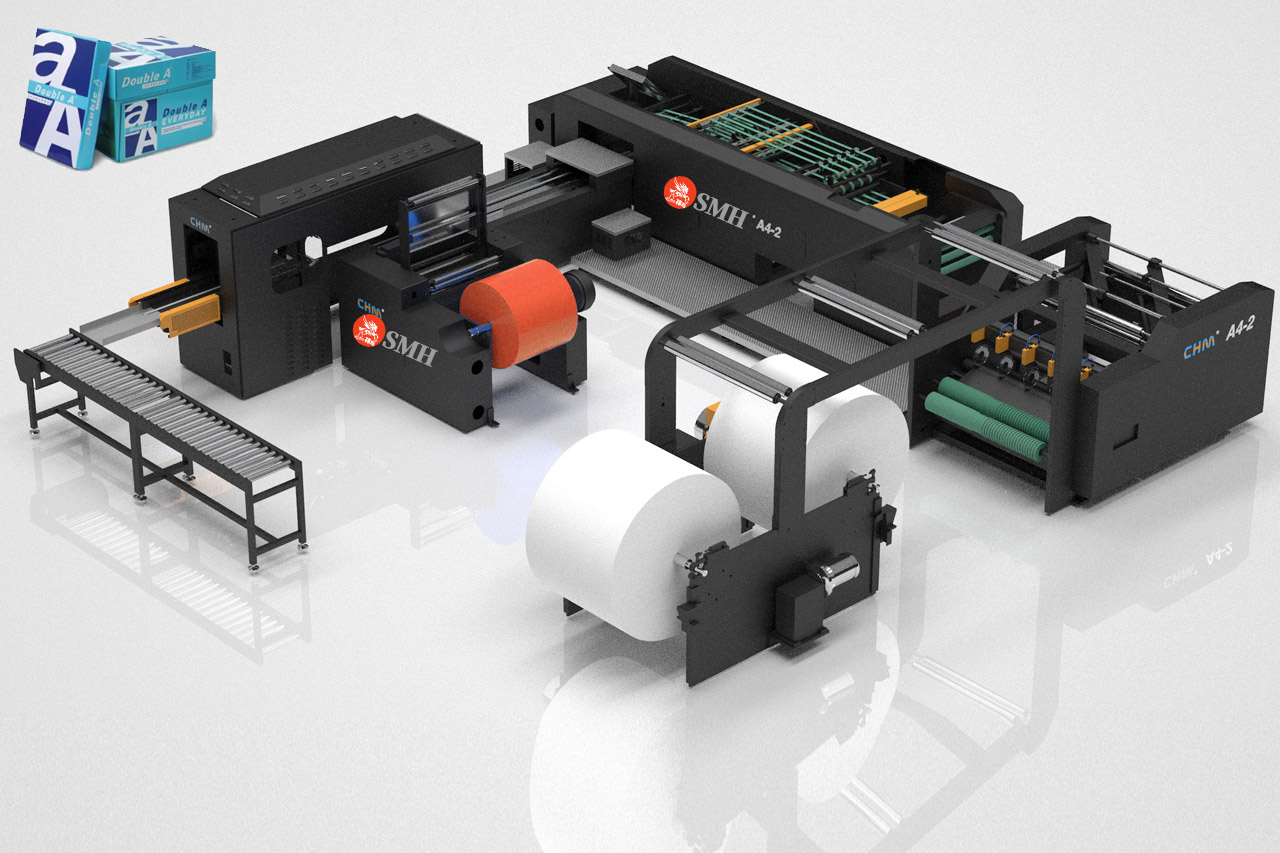

Modern folding machines are versatile, easily accommodating common folding styles such as bifold, accordion, and map folds. They can adapt to different paper weights, from thick cardstock to delicate rice paper, providing suitable solutions for all.

Invest in the right folding machine today to unleash your creativity, streamline production, and enhance precision. Start exploring now and unlock the potential of automated, professional manufacturing!

How to Choose the Right Folding Machine for Your Business

- Define Your Needs and Budget: Start by identifying your primary folding types, frequently used paper sizes, and expected production volume. Entry-level manual machines are ideal for low-frequency, simple folds, while automatic CNC models greatly boost efficiency and support business growth.

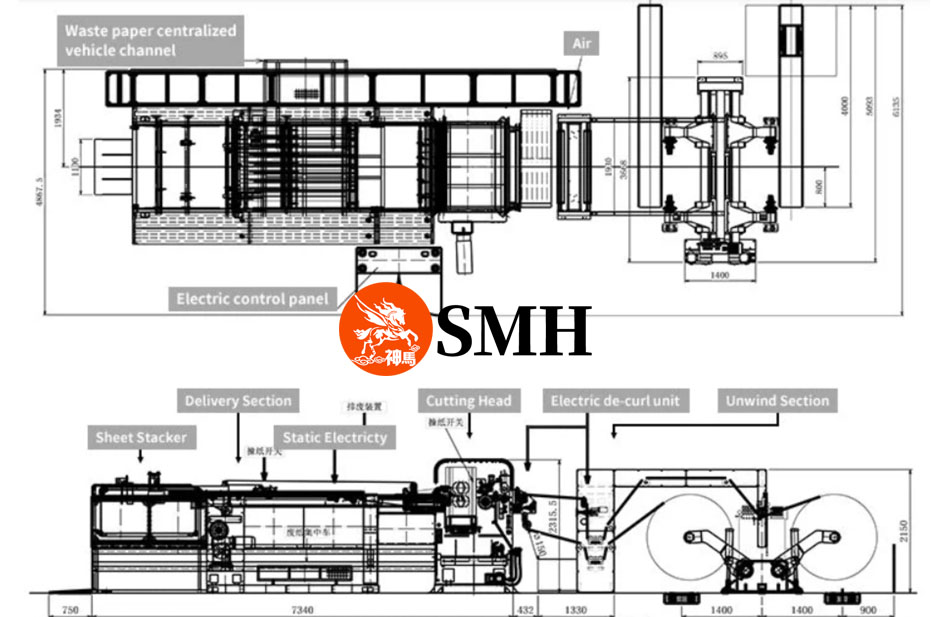

- Prioritize Core Performance: Evaluate the machine’s folding accuracy, speed, minimum and maximum fold sizes, and paper compatibility. Stability and durability ensure a reliable long-term investment.

- Consider Space and Usability: Since factory space is often limited, opt for a compact, easy-to-operate machine. Features like clear instructions and quick setup help you get started without delay.