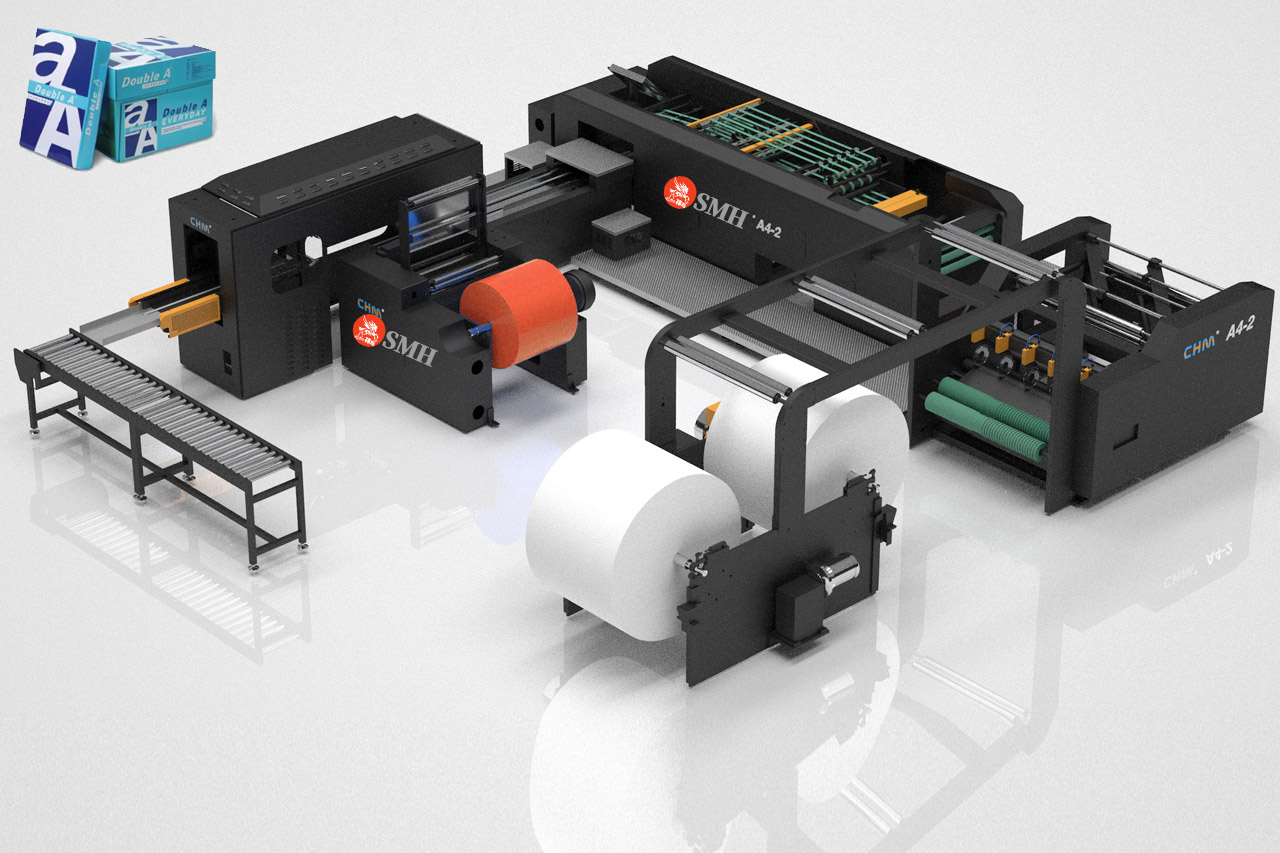

The key advantage of this system is its precise adaptation to medium-to-long-run processing needs, which require continuous, stable paper feeding. Traditional machines must stop frequently to change paper, disrupting workflow, increasing downtime, and complicating operations. This system solves these issues with a “non-stop paper feeding” mode: when one paper supply nears depletion, another is replenished without halting the machine, enabling seamless feeding. This approach eliminates the downtime and waiting periods typical of conventional feeders, ensuring continuous operation and minimizing efficiency losses.

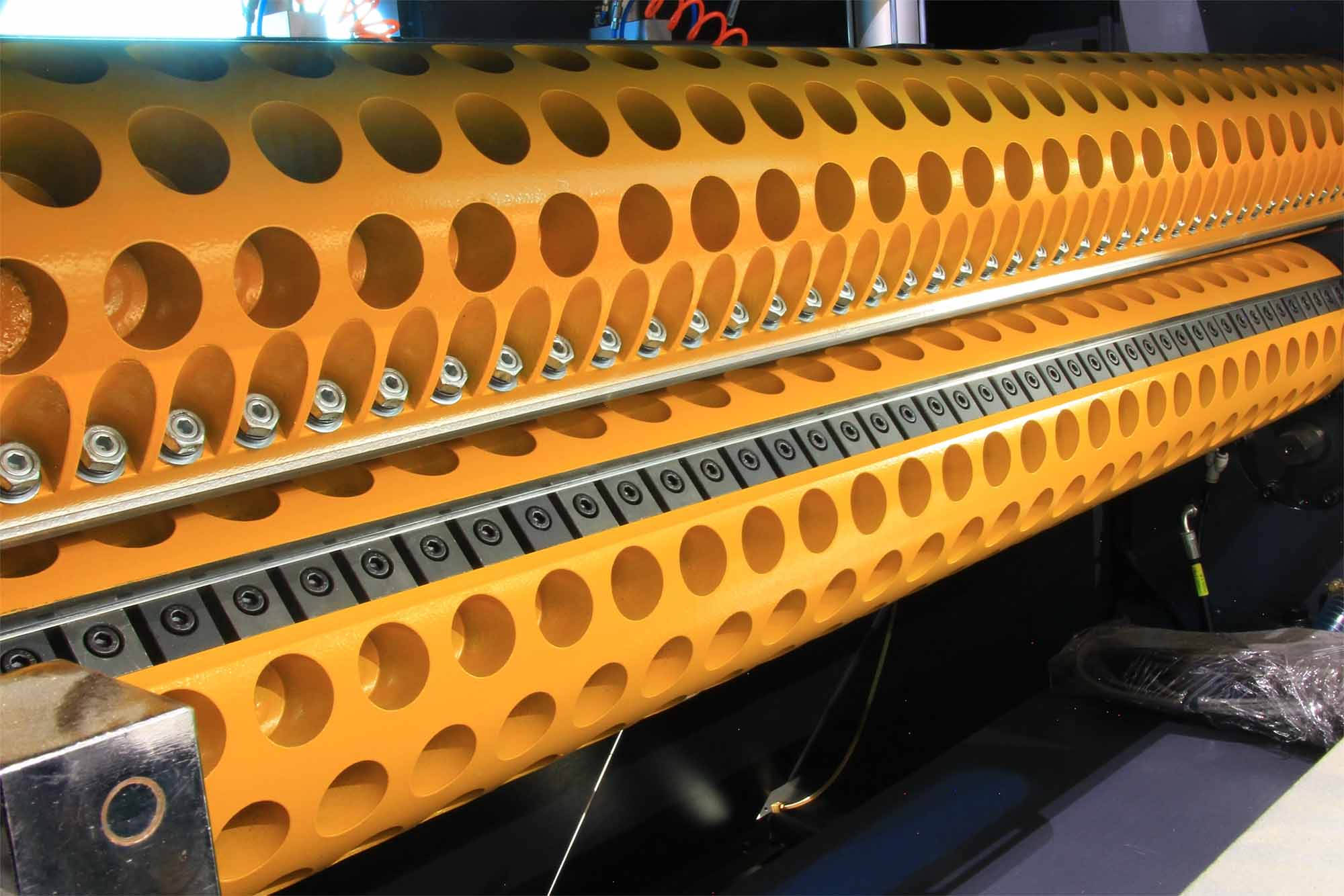

Additionally, the circulating paper feeder excels in handling a wide range of paper types, including “special” papers that challenge traditional systems. For wrinkled or uneven paper commonly seen in printing, its optimized suction mechanism and feeding path ensure smooth, stable paper transport, preventing jams and folding errors. It also effectively processes pre-folded, pre-cage-stamped, and pre-perforated papers, further expanding its versatility and reliability in diverse production scenarios.

From an industry perspective, as printing and packaging demand higher production efficiency, better quality, and stricter cost control, the value of the recirculating paper feeder system becomes increasingly clear. It not only strengthens the market competitiveness of folding machines but also helps companies optimize processes and improve their core strengths. Whether serving the large-scale production needs of small and medium enterprises or the efficiency goals of large corporations, this stable, efficient, and flexible system revitalizes the paper processing industry and drives it toward greater productivity and quality.