Pile Turner Reduces Labor for Paper Reversing/Paper Alignment/Pallet Replacement High-end Auto Pile Turner.

Pile Turner Reduces Labor for Paper Reversing/Paper Alignment/Pallet Replacement High-end Auto Pile Turner

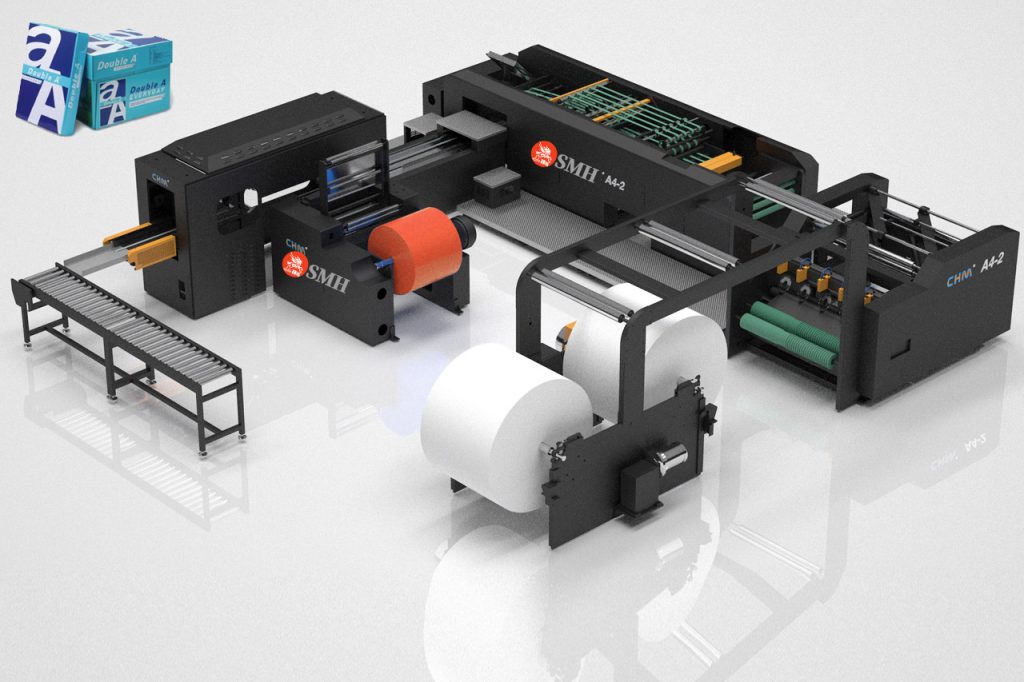

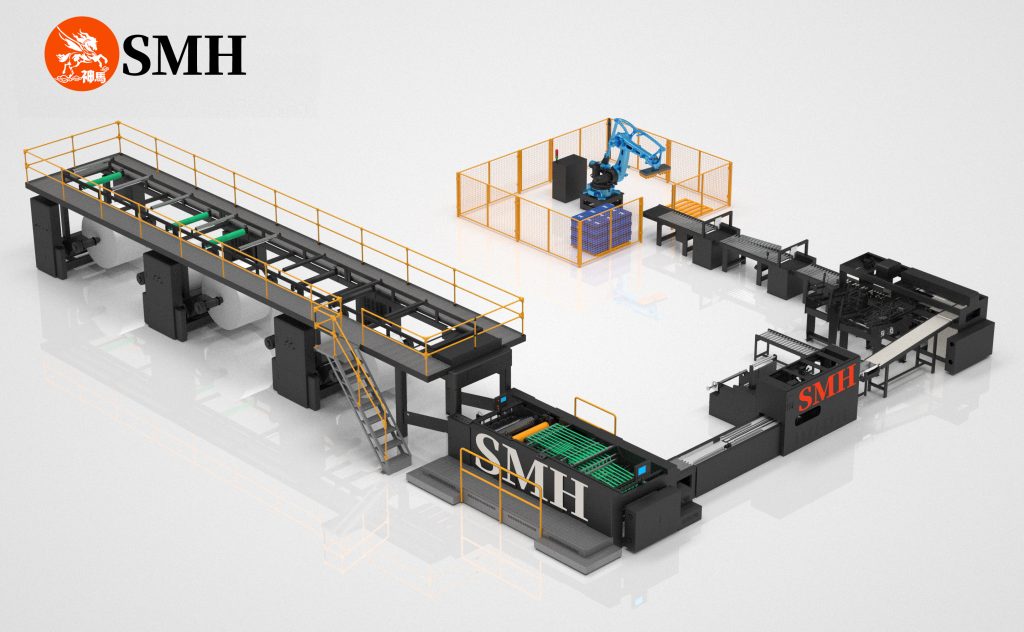

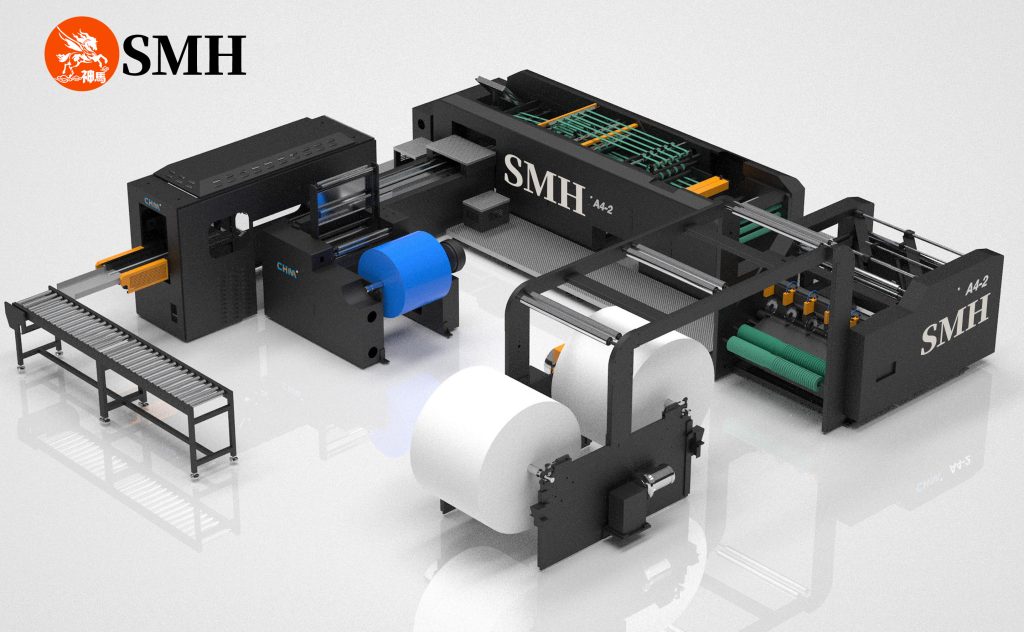

SHM a collection of high-end automatic pile turners, introduced to further enhance the SMH lineup. With its user-friendly design, paper turning and pallet replacement can be easily initiated from the touchscreen control panel, conveniently located in a safe position. This ensures that anyone can operate the machine safely and confidently.

Concept

The SMH Pile Turner series is designed with advanced automation features that make it simple and safe to align paper. This innovation simplifies paper handling, helping to optimize printing processes and enhance efficiency.

After installation, automatic operation can begin immediately thanks to pre-installed programs (such as turning, aeration, and alignment). All functions, including program selection, job loading, configuring feature settings, and switching to manual mode, can be managed effortlessly through the touch panel. Moreover, the SMH pile turner is engineered to work efficiently in limited spaces. Loading, output, and pallet raising/lowering are all handled in one convenient location. The SMH Pile Turner has successfully passed rigorous European safety standards, ensuring reliability and peace of mind.

Features

- Automatic operation can be seamlessly activated from the intuitive touch panel control desk.

- Advanced paper alignment is achieved using a three-row air blower vibration system for precision and consistency.

- Safety features for turning, raising, and lowering come standard, ensuring secure operation at all times.

- Switch between automatic and manual modes with just a single button press, offering flexibility and convenience.

- Comes equipped with optional pallet clamps for enhanced functionality.

Introduction

The fully automatic pile turner is designed to efficiently flip paper piles during double-sided printing operations. Additionally, it enables operators to swiftly change pallets, align and condition piles in a time-saving manner, eliminate ink odors, and remove dust through aeration. Pile turners are indispensable for replacing manual labor, enhancing productivity and print quality, and separating sheets to prevent misfeeds in paper handling equipment. Our machines comply with CE standards and are engineered for high operational safety and ease of use.

Functions of the Pile Turner

The pile turner serves not only as a flipping unit but also provides the following functionalities:

- Flipping the pile

- Aligning the pile

- Airing (with optional ionized air)

- Dust removal

- Separating cutting edges

- Removing spray powders

- Drying (optional)

- Eliminating ink odor

- Centering the pile

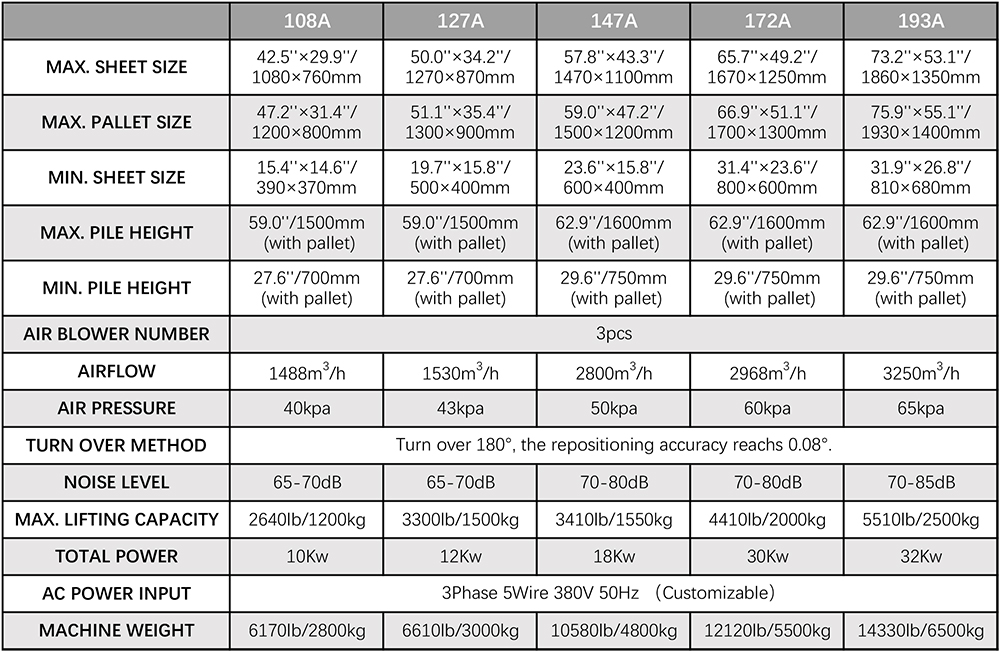

Specification