The Efficient application and Innovative Practice of SMH Folding Machines in Pharmaceutical Packaging

The SMH folding machine used in pharmaceutical packaging printing factories is a powerful tool for innovating medical packaging

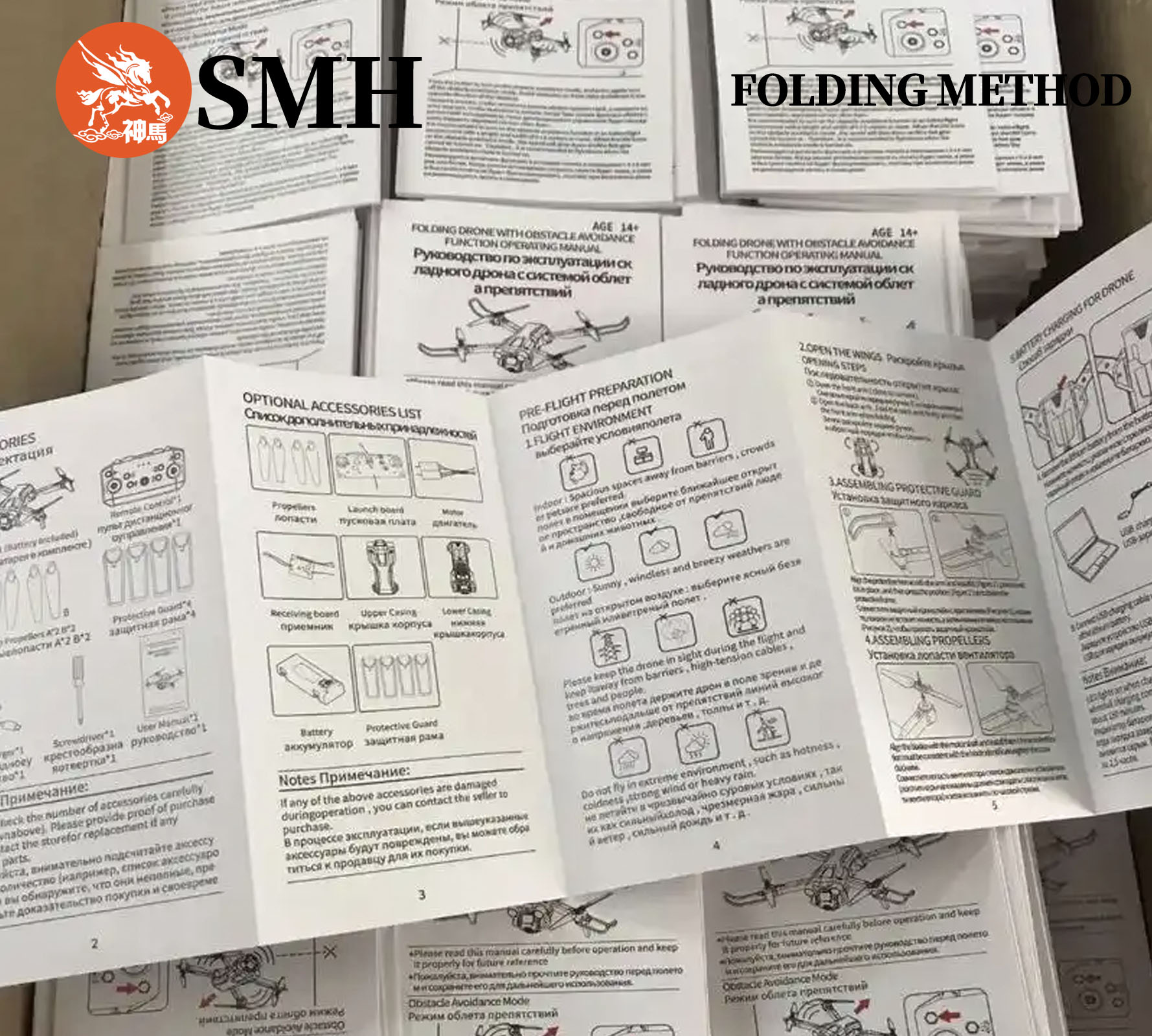

In the pharmaceutical industry, the printing and packaging of product instructions are particularly important. Especially for exported pharmaceutical products, their instructions often need to cover multiple languages and be quite long, which poses a considerable challenge to printing equipment. In order to adapt to the specifications of outer boxes and smoothly integrate into the automated packaging production line, pharmaceutical enterprises have chosen to use folded instruction manuals one after another to ensure the efficiency and flexibility of printing. The SMH drug instruction manual folding machine, with its efficient and precise performance, has become the ideal choice to meet this demand.

The Application of SMH Folding Machine in Pharmaceutical Packaging

High efficiency and precise performance

In the field of pharmaceutical packaging, SMH folding machines stand out with their outstanding performance. This folding machine is not only highly efficient and precise, but also can perfectly adapt to the specifications of outer boxes, easily integrating into automated packaging production lines and helping pharmaceutical enterprises achieve high efficiency and flexibility in printing. The SMH folding machine, with its high efficiency and precise performance, performs outstandingly in pharmaceutical packaging and meets the printing requirements of multi-language instructions.

High-speed production

The SMH folding machine is equipped with high-speed folding capabilities and can easily complete a large number of folding tasks in a short time. Its production speed can reach up to 6,000 sheets per hour, significantly enhancing the production efficiency of pharmaceutical packaging.

Precise detection

The SMH folding machine is equipped with cutting-edge technologies, including double-sheet inspection and anti-mixing inspection systems, ensuring that each instruction manual undergoes precise inspection, thereby effectively guaranteeing the printing quality. These detection systems ensure the printing quality of the instruction manual.

Flexible adaptation

The SMH folding machine is not only technologically advanced but also has diverse functions. It can easily handle paper of different weights, ranging from 35 to 120g, meeting various printing needs. In addition, this machine also offers a variety of folding modes, such as organ folding and core folding, providing customers with flexible and diverse folding options. It can handle paper of various weights, offer multiple folding modes and has strong adaptability.

Automated system

The SMH folding machine is also equipped with advanced automation functions, such as an automatic collection unit, which make the production process more efficient and smooth. Automated functions such as automatic collection units have enhanced production efficiency.

Convenience and efficiency

The SMH folding machine is designed very humanely, making it convenient to operate on the machine and easily integrated into the automated packaging production line. Its unique adaptability enables it to be adjusted according to the specifications of the outer box, thereby effectively reducing the occupied space. In addition, its compact size after folding makes it convenient for patients to carry around, providing them with a convenient channel to access relevant information about drugs at any time. This machine is designed for easy operation, suitable for automated packaging lines, and saves space.

Reduce printing costs

When transmitting the same amount of drug information, the instruction manual designed with the SMH folding machine has a lighter paper weight compared to the traditional single-page instruction manual. The advantage of using lightweight paper to design the specification not only helps save resources but also significantly reduces printing costs.

Enhance brand image

Through meticulous design and layout, various types of information in the drug instructions are effectively classified and arranged, enabling patients to quickly find the content they need when consulting. This convenient query experience not only enhances patients’ understanding of the drug instructions but also helps to shape the overall positive image of the drug brand.