Description

Folder Machine Series

Buckle Folding Machine / Pharmaceutical Insert Folding Machine

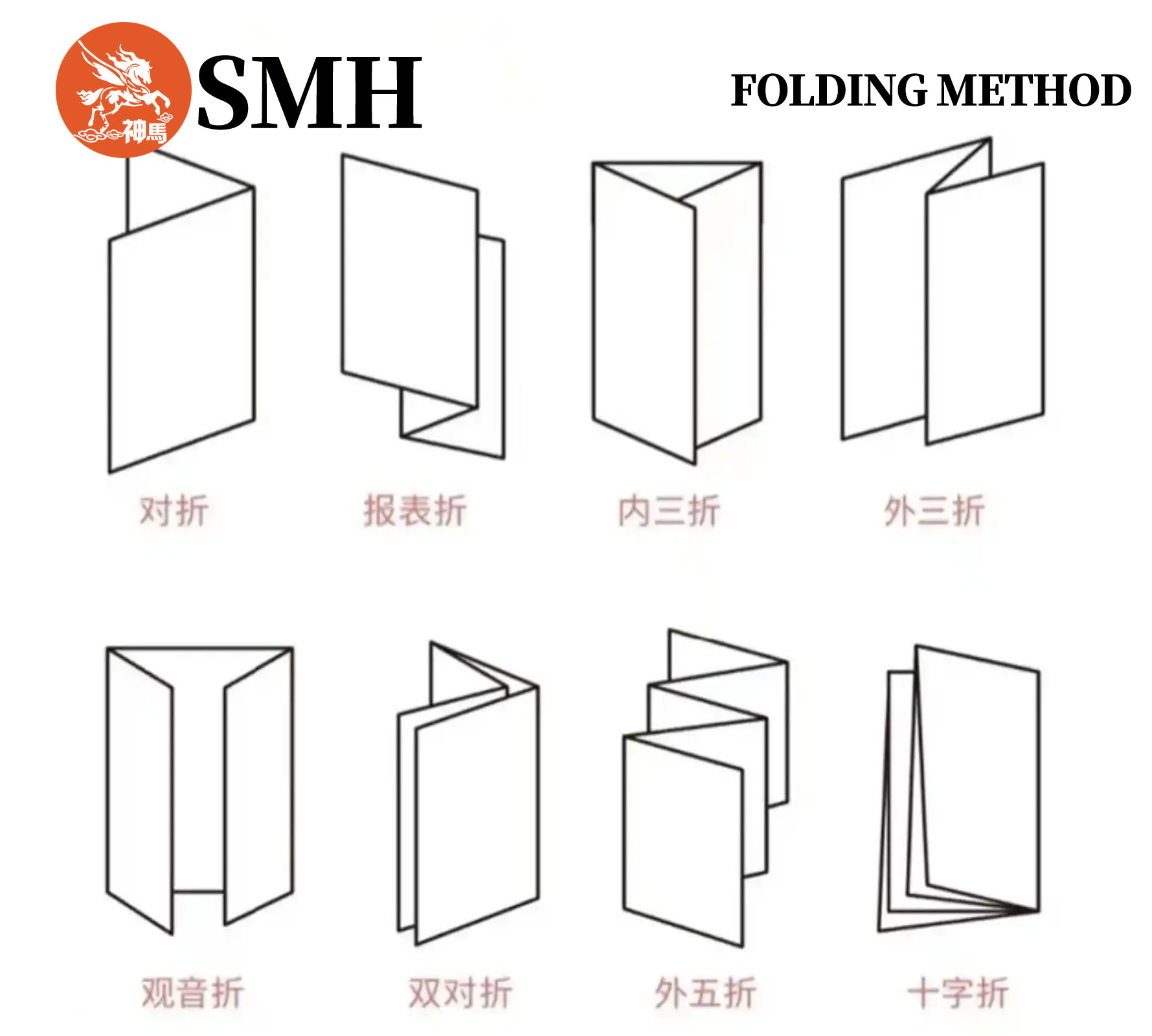

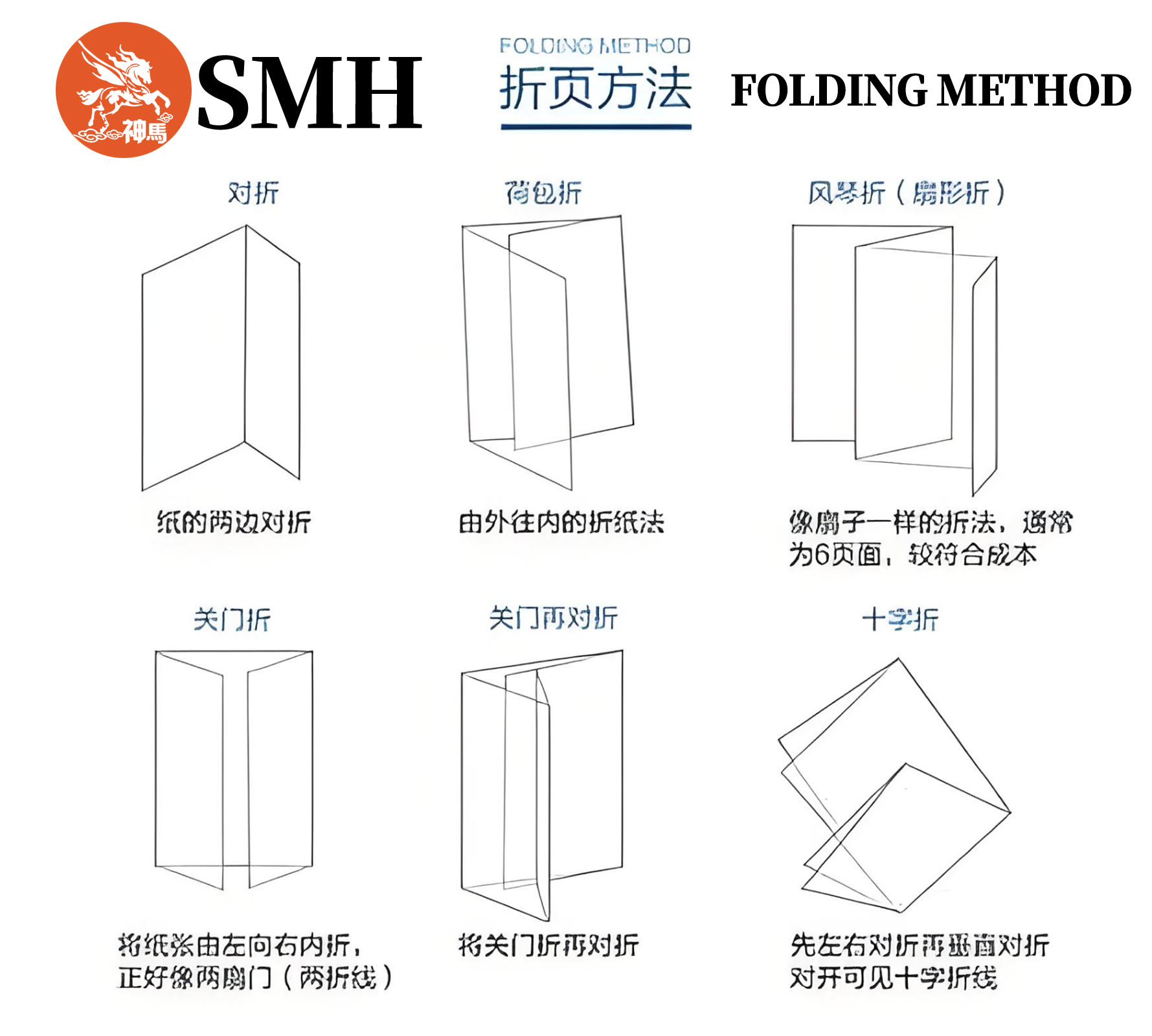

Folding Technology

We offer a wide range of folding solutions tailored to the SMH buckle folding machine series, ensuring compatibility with pharmaceutical inserts and other complex folding requirements.

Technical Specifications

-

Place of Origin: Dongguan, China

-

Brand: SMH – Insert Folding Machine

-

Certification: CE Certified

-

Model Name: Pharmaceutical Outsert System

-

Maximum Fold Thickness: 15 mm

-

Minimum Finished Size: 30 × 30 mm

-

Maximum Finished Size: 160 × 90 mm

-

Paper Weight Range: 35–200 g/m²

-

Maximum Roller Speed: 180 m/min

-

Power Consumption: 7.0 kW

-

Voltage: 380 V

-

Air Pressure Requirement: 0.6 MPa

-

Machine Dimensions: 3700 × 8000 mm

-

Drive System: Gear transmission

-

Optional Configurations: Independent knife unit, parallel knife, labeling system, hot melt gluing system

-

Packaging: Export-standard wooden case

Commercial Terms

-

Minimum Order Quantity: 1 Set

-

Price: Negotiable

-

Packaging: Export-standard wooden case

-

Delivery Time: 20–30 Days

-

Payment Method: T/T

-

Supply Capacity: 700 sets/year

Product Overview

The T520/T600 Pharmaceutical Leaflet Folding Machine, part of the SMH Outsert System, is designed for precision folding of pharmaceutical inserts. With a working width of 520 or 600 mm and a length of 1000 mm, it ensures reliable performance even with intricate folding patterns.

Equipped with a camera inspection system, ultrasonic double-sheet detection, and online delivery, this machine provides consistent quality control. Additional features include:

-

Gear Drive Transmission – Ensures stable folding and reduces maintenance frequency.

-

Efficient Paper Feeding – Suction rollers and ball guides guarantee smooth alignment.

-

High-Performance Folding Knife – Powered by Festool pneumatic components for fast, stable, and powerful operation.

-

Noise Reduction & Ergonomics – Integrated soundproofing and a convenient conveyor table.

-

Multi-Function Capabilities – Supports drilling, scoring, and cutting for diverse applications.

-

Advanced Control System – Keyence PLC for precise and reliable automation.

-

Glue Application System – HHS glue spray gun compatible with a wide range of adhesives.

-

Flexible Add-ons – Electric lifting controls on vertical stacker, parallel knife, and flattening units, enabling independent operation.

-

Quality Assurance – In case of double sheets or printing errors, the pneumatic guide plate lifts automatically while the servo system removes defective sheets without halting production.