Benefits

- Increases productivity by minimizing manual handling.

- Improves print quality by removing dust and aligning sheets.

- Reduces labor costs and worker strain.

- Prevents paper jams in downstream equipment.

Its main function is to lift, turn, and align stacks of paper, cardboard, or other flat materials, facilitating efficient handling during production processes. Here’s a breakdown of what a pile turner does and why it’s useful:

Introduction

The fully automatic pile turner is designed to efficiently flip paper piles during double-sided printing operations. Additionally, it enables operators to swiftly change pallets, align and condition piles in a time-saving manner, eliminate ink odors, and remove dust through aeration. Pile turners are indispensable for replacing manual labor, enhancing productivity and print quality, and separating sheets to prevent misfeeds in paper handling equipment. Our machines comply with CE standards and are engineered for high operational safety and ease of use.

Functions of the Pile Turner

The pile turner serves not only as a flipping unit but also provides the following functionalities:

- Flipping the pile

- Aligning the pile

- Airing (with optional ionized air)

- Dust removal

- Separating cutting edges

- Removing spray powders

- Drying (optional)

- Eliminating ink odor

- Centering the pile

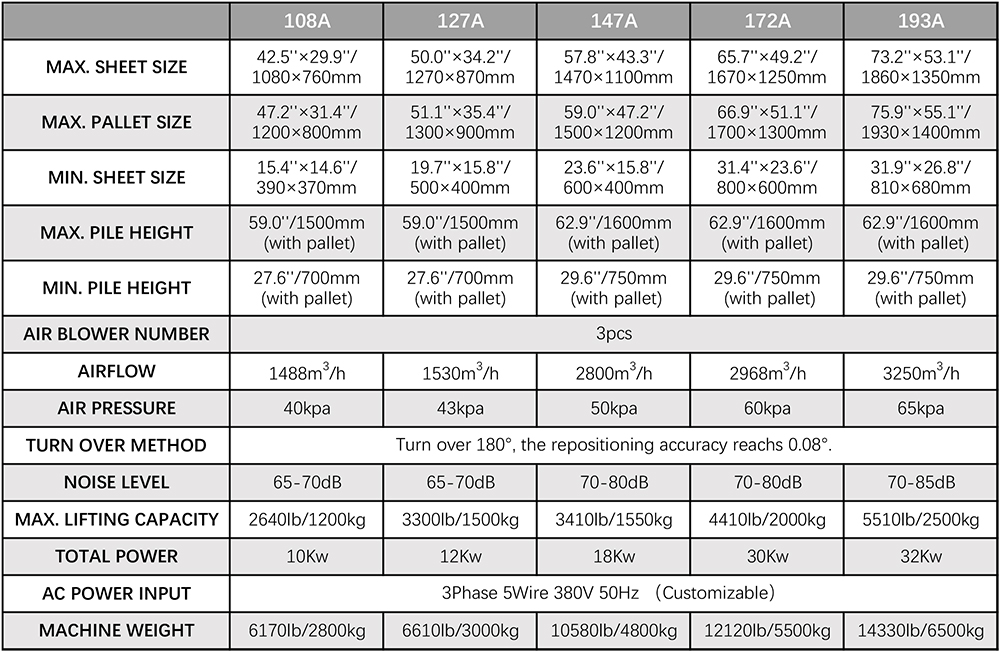

Specification

| 108A | 127A | 147A | 172A | 193A | |

| MAX. SHEET SIZE | 42.5″x29.9″/1080x760mm | 50.0″x34.2”/1270x870mm | 57.8″x43.3″/1470x1100mm | 65.7″x49.2″/1670x1250mm | 73.2″x53.1“/1860x1350mm |

| MAX. PALLET SIZE | 47.2″x31.4″/ 1200x800mm | 51.1″x35.4″/ 1300x900mm | 59.0″x47.2″/1500x1200mm | 66.9″x51.1″/ 1700x1300mm | 75.9″x55.1“/1930x1400mm |

| MIN. SHEET SIZE | 15.4”x14.6″/390x370mm | 19.7″x15.8″/500x400mm | 23.6″x15.8″/600x400mm | 31.4″x23.6″/800x600mm | 31.9″x26.8”/810x680mm |

| MAX. PILE HEIGHT | 59.0″/1500mm(with pallet) | 59.0″/1500mm(with pallet) | 62.9″/1600mm(with pallet) | 62.9″/1600mm(with pallet) | 62.9″/1600mm(with pallet) |

| MIN. PILE HEIGHT | 27.6”/700mm(with pallet) | 27.6”/700mm(with pallet) | 29.6”/750mm(with pallet) | 29.6”/750mm(with pallet) | 29.6”/750mm(with pallet |

| AIR BLOWER NUMBER | 3pcs | 3pcs | 3pcs | 3pcs | 3pcs |

| AIRFLOW | 1488m³/h | 1530m³/h | 2800m³/h | 2968m³/h | 3250m’/h |

| TURN OVER METHOD | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° |

| NOISE LEVEL | 65-70dB | 65-70dB | 70-80dB | 70-80dB | 70-85dB |

| MAX. LIFTING CAPACITY | 2640lb/1200kg | 3300lb/1500kg | 3410lb/1550kg | 4410lb/2000kg | 5510lb/2500kg |

| TOTAL POWER | 10Kw | 12Kw | 18Kw | 30Kw | 32Kw |

| AC POWER INPUT | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) |

| MACHINE WEIGHT | 6170lb/2800kg | 6610lb/3000kg | 10580lb/4800kg | 12120lb/5500kg | 143301b/6500kg |

| AIR PRESSURE | 40kpa | 43kpa | 50kpa | 60kpa | 65kpa |