Difficulties in slitting gold card paper? The double-blade series of Changjiang Machinery is here to break the deadlock, offering a brilliant solution for efficient production!

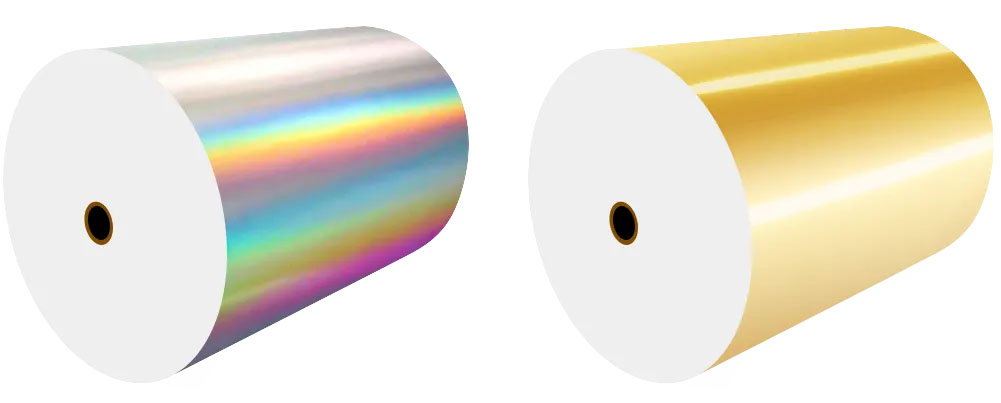

In the packaging and printing industry, gold card paper holds an important position due to its unique advantages. It is hard in texture, with a naturally lustrous surface and a rich variety of colors. Common gold and silver colors exude a high-end feel. There are also aluminum foil gold card paper and PET aluminum film gold card paper, etc. The color, depth and brightness can all be adjusted. The surface can be treated with high gloss and matte finish, and can also be pressed into various styles. It is widely applied in the production of packaging boxes and cartons for industries such as fast-moving consumer goods, cosmetics, pharmaceuticals, and gifts.

The types of backing paper for gold card paper are also very diverse, including white card, coated plate, double-sided adhesive, recycled paper, gray board paper, white backing with white, red backing and many other options. Moreover, the customized services for various gold card papers, silver card papers and packaging boxes can ensure the quality and effect of the printed products before batch printing, laying a good foundation for subsequent production.

However, although gold card paper is good, slitting is not an easy task and has relatively high requirements for slitting. The CHM-SGT double-blade series synchronous double-drum slitting machine of Changjiang Machinery has performed astonishingly well in the slitting of gold card paper, perfectly solving many problems.

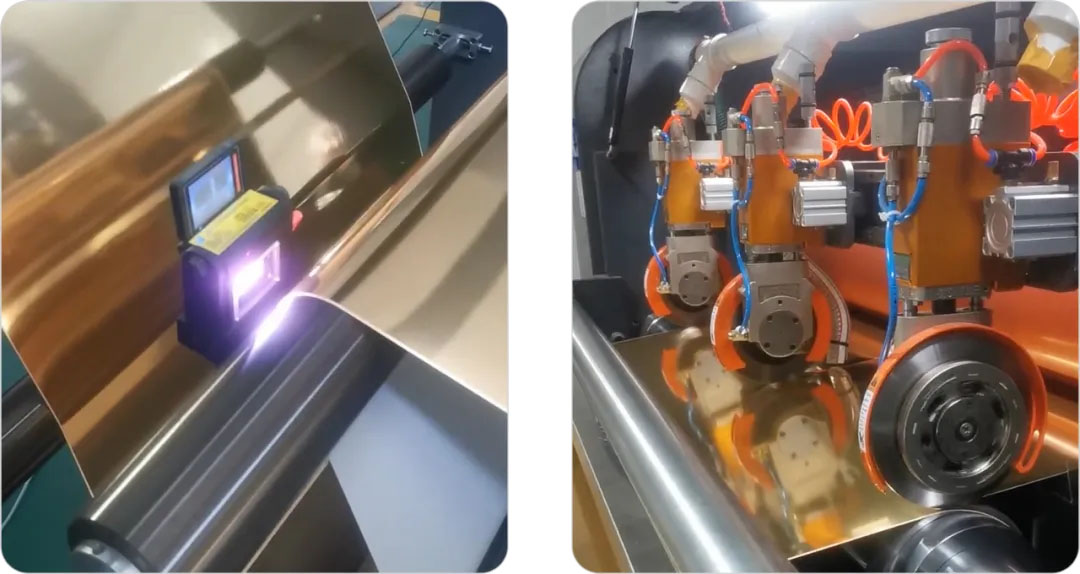

At the first production site, we can clearly see the outstanding performance of the CHM-SGT double-blade series synchronous double-drum slitting machine. It is equipped with an edge alignment and line guiding system controller, which can achieve automatic edge alignment. It is also fitted with a pneumatic slitting knife dust removal device. During the production process, the efficient production state of slitting and trimming from one to two is impressive.

Looking at the second production site, its high-speed slitting further demonstrates the stability and strong production capacity of Changjiang Shuangdao.

The double-blade series is a popular series of Changjiang Machinery, specially developed for slitting thick paper. When it comes to slitting gold card paper, it has many outstanding features. Firstly, it can effectively solve the problem of paper fibers, which has always been a thorny issue in thick paper slitting, but the double-blade series of Changjiang Machinery can easily overcome it. Secondly, it meets the demands of high grammage and high precision. The paper after slitting has no light spots or indentation marks and can be directly printed on the printing machine, which greatly improves production efficiency.

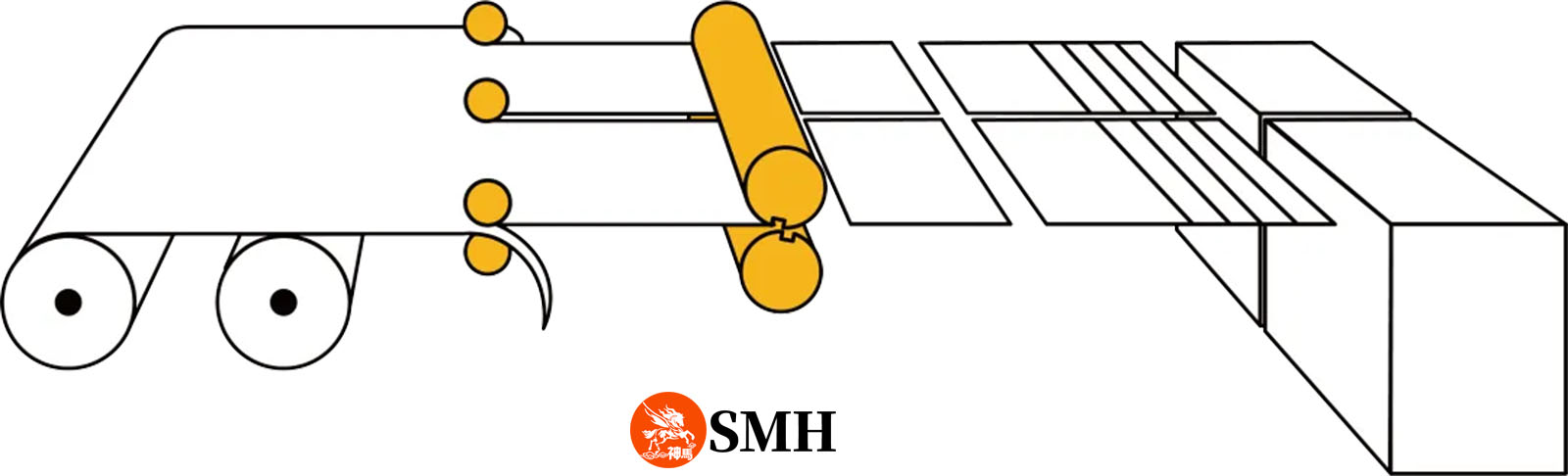

▲ Automatic tool arrangement system

▲ High-precision technology blade head

Not only that, this series of slitting machines can also be equipped with advanced automatic positioning slitting knife technology to achieve automatic knife arrangement, which is more efficient and brings significant improvements to users’ economic benefits, production speed and finished product quality. The high-precision technology blade head ensures high precision and high production capacity in paper slitting, while achieving low loss. It performs impressively when slitting 100-1000 grams of paper, and can handle both thick paper and high-grammage paper with ease.

The double-blade series slitting machines of Changjiang Machinery have shone brightly in the field of gold card paper slitting, thanks to their outstanding performance. It not only solves various problems in the traditional slitting process, but also reduces costs and improves benefits for enterprises through efficient and high-precision production. It is a powerful assistant in the production and processing of gold card paper. If you are also troubled by the problem of slitting gold card paper, you might as well take a look at the double-blade series slitting machines of Changjiang Machinery. We believe it will bring unexpected improvements to your production!

-END-

SMH Machinery is a professional manufacturer of web paper slitting machines and a domestic professional provider of solutions for paper product processing. Established in 2004, the company covers an area of 150,000 square meters and has the most professional production technology force and full life-cycle after-sales service team in the entire industry. It has received high praise from customers at home and abroad.

Main products: High-speed web paper slitting machine, double rotary knife web paper slitting machine, A3/A4/A5 copy paper production line, paper packaging machine, luggage machine, intelligent palletizing robot, all-electric forklift for handling base paper rolls