For a lot of paper companies, dealing with rough edges on cut paper is a real pain. When we need to cut a big stack of paper, we usually just pile it all up together because of time and size constraints, hoping to get the job done in one go. But when there’s too much paper stacked up, it often leads to misalignment or shifting during the cutting process. This causes uneven cuts on each sheet, and because the force isn’t applied evenly, the edges end up being rough.

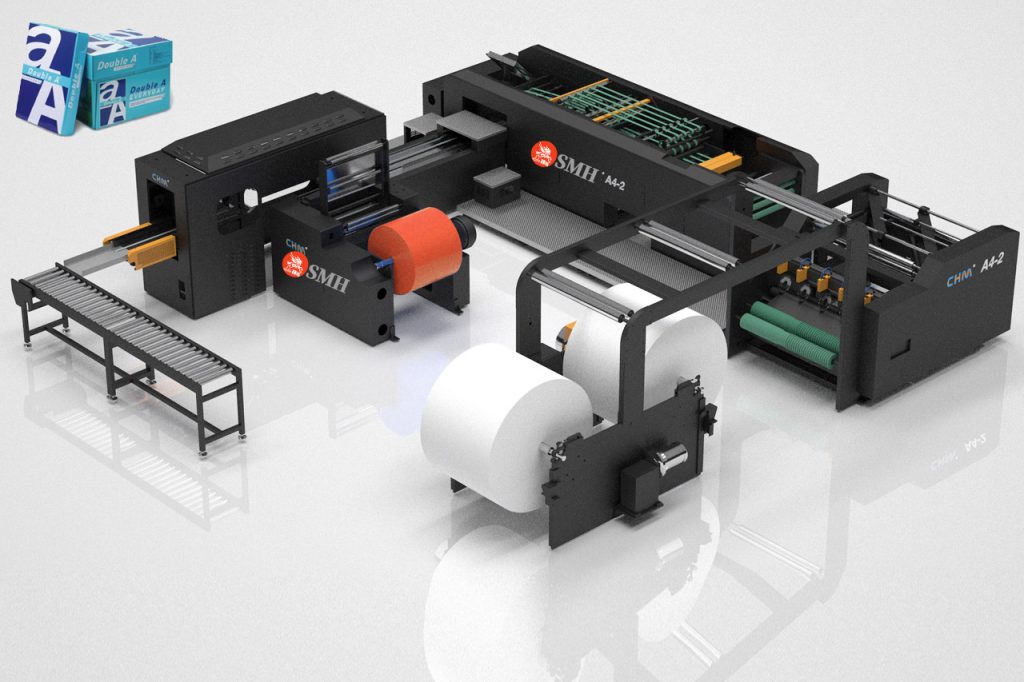

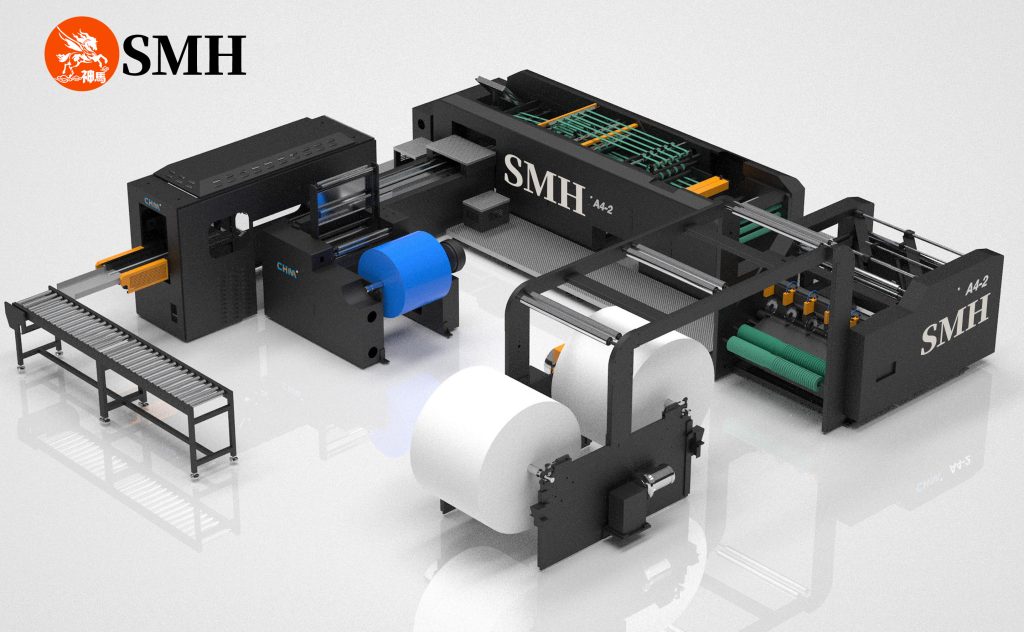

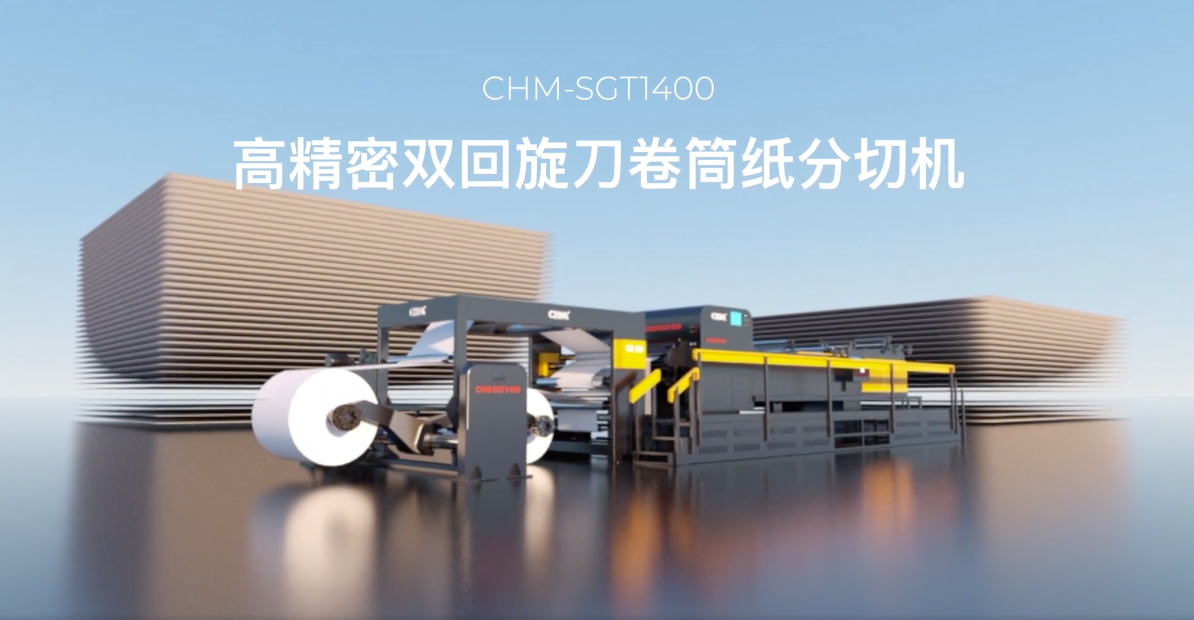

To tackle this issue, SMH has come up with a double-knife slitting machine after years of development. It uses two rotating knife shafts at the top and bottom for cutting, which ensures high precision. After high-speed slitting, the edges of the paper are smooth and clean, with no burrs, light spots, or indentations. This completely solves the problem of paper fibers and allows the slitted products to be printed directly without any extra processing.

So, how exactly does SMH’s double-knife system fix the issue of paper fibers? The double knives from Changjiang Machinery use a trailing slitting design with advanced technology in the knife heads. While waiting for the paper to be fed in, the knife heads stay still. Only when the paper reaches the set size does the upper and lower knife heads suddenly accelerate to the edge and slit the paper simultaneously. This guarantees that the edges are flat and clean, leaving no paper fibers behind. Plus, the edge and corner adjustments are already fixed by the knife head before the machine leaves the factory. During slitting, the squareness of the flat paper is ensured without needing further adjustments.

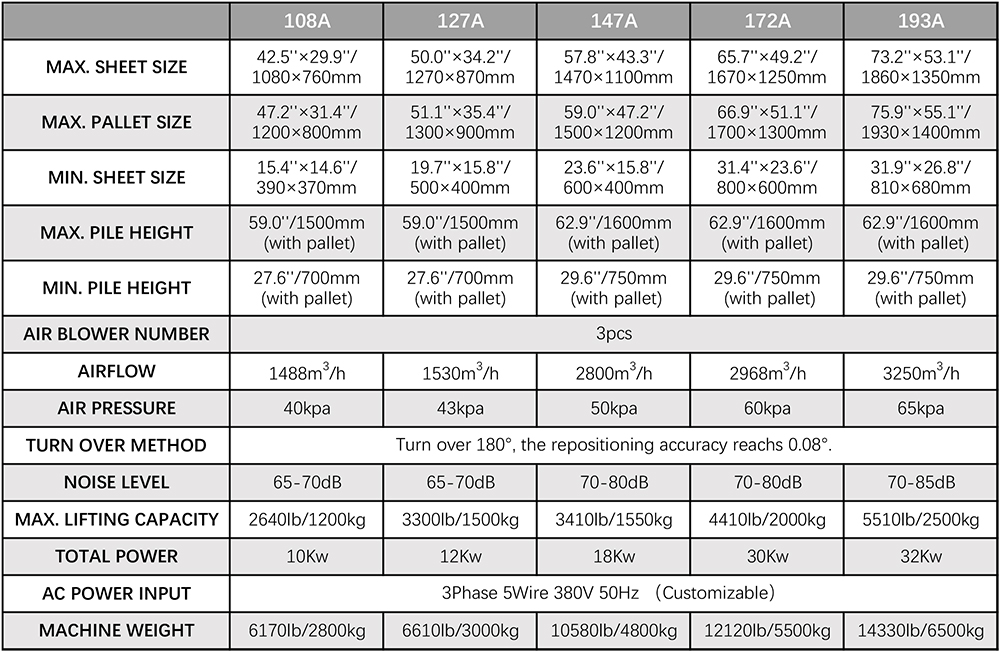

Here’s a bit more about the equipment:

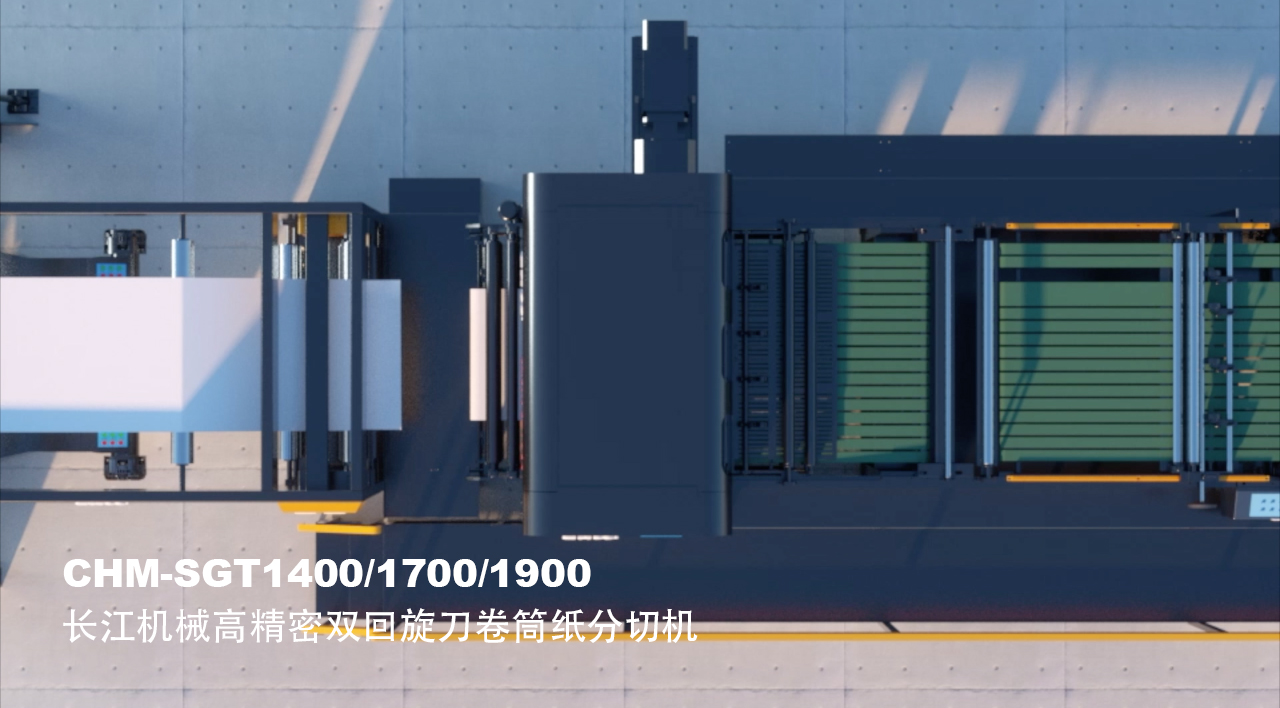

- Base Paper Rack: Delta arms oil base paper can handle rolls with a maximum diameter of 1.8 meters and widths of 1100 mm, 1400 mm, 1700 mm, or 1900 mm.

- Cross-Cutting Knife Set: The double roller knife rotates at the best angle, ensuring square edges and no paper fibers, making it ready for direct printing.

- Cross-Cutting Blade: Depending on the type of paper, high-quality alloy steel is used for durability, wear-resistance, and a clean cut.

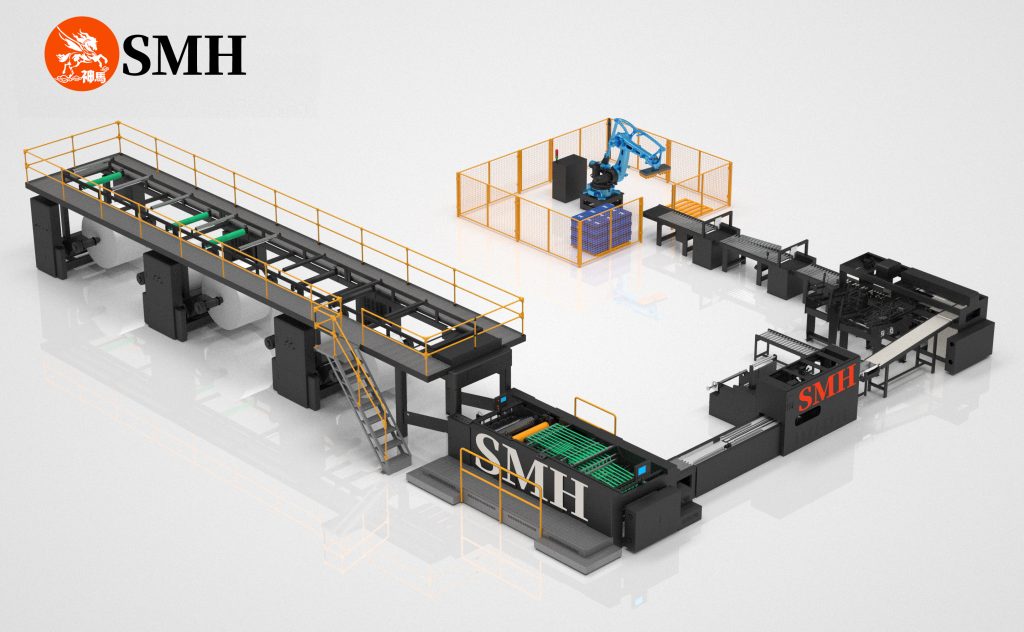

- Special Features: This equipment is designed specifically for thick paper. It can slit at speeds up to 300m/min, with a weight range of 100-1000g. For optimal performance, it’s recommended to use paper weighing 200g or more per sheet, like 250g. It can slit up to 4 rolls simultaneously, boosting efficiency and maximizing production capacity.

SMH has always been highly regarded by customers both domestically and internationally. Its market share keeps growing, earning trust and recognition from a wide range of customers. This success is due not only to its perfect quality management system and pursuit of excellence but also to its continuous R&D efforts and spirit of innovation.

First-Class Service:

When SMH delivers a double-drum slitting machine to you, they’ll also train your operators until they’re fully confident in using the machine and can start cutting paper independently. If you ever need to train new operators, SMH regularly holds paper-cutting engineer training camps—feel free to join! Besides these services, Changjiang Machinery offers additional unique services:

- Remote inspection

- Annual machine inspection

- Spare parts and services

- Annual machine maintenance

- Productivity analysis

The Technical Support Center (TSC) provides 24/7 service, including:

- Problem-solving and cooperative discussions

- Warranty period summary visits

- Annual machine maintenance