Cutting Machines

Paper Roll to Sheet Cutting Machine

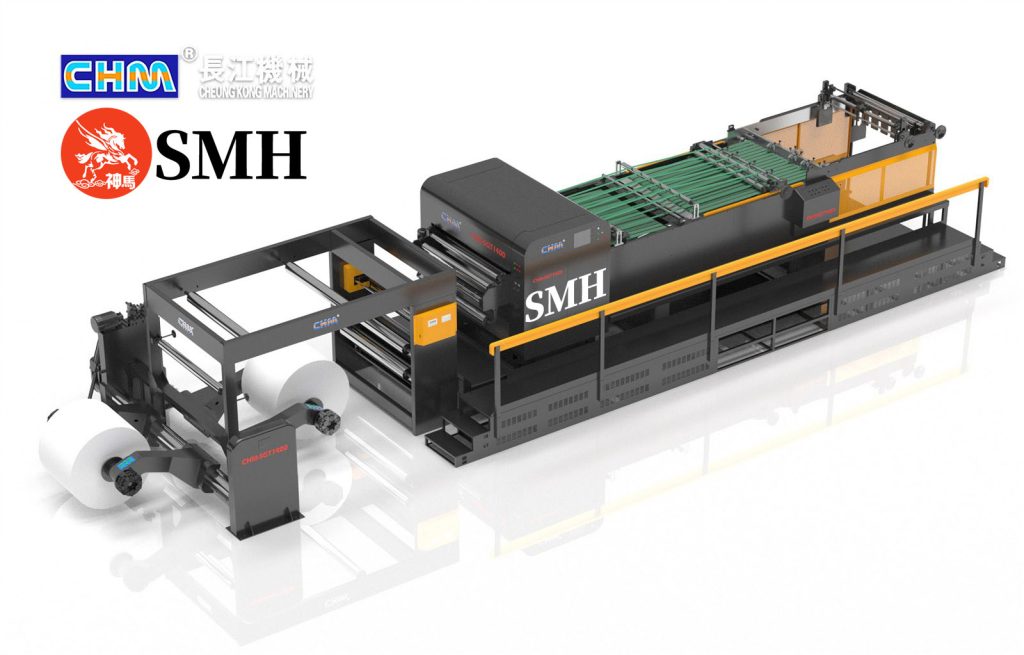

Cutting Machine Photo

Paper Roll to Sheet Specifications

Cutting Machines

Paper Roll to Sheet Cutting Machine

Cutting Machine Photo

Paper Roll to Sheet Specifications

CHM-1400 Single Sheeter Machine SMH Series

We’re a professional manufacturer of sheeting machines and one of the leading paper sheeting solution providers in China. Our machines are mainly used for paper sheeting in paper mills, printing houses, and other similar industries. The process includes: unwinding, cutting, conveying, and collecting. It’s really easy to operate!

Process flow: Unwinding → Loading → Transverse Cutting → Conveying → Collecting; primarily designed for paper products.

Product Introduction

SMH Series

| Model | CHM-1400 | CHM-1700 | CHM-1900 | CHM-1100 |

| 1. Type of cutting | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed |

| 2. weight of paper | 60-550 GSM | 60-550 GSM | 60-550 GSM | 60-550 GSM |

| 3..reel diameter | Max 1800mm (71″) | Max 1800mm (71″) | Max 1800mm(71″) | Max 1800mm(71″) |

| 4. Finished width | Max 1400mm (55″) | Max 1700mm (66.9″) | Max 1900mm(74.8″) | Max 1100mm(74.8″) |

| 5. Finished sheet-Length | Min.450-Max.1650 mm | Min.450-Max.1650 mm | Min.450-Max.1650 mm | Min.450-Max.1650 mm |

| 6. Num.of rolls cutting | 2 rolls | 2 rolls | 2 rolls | 2 rolls |

| 7. Cutting accuracy | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) |

| 8. Max.speed of cutting | 300cuts/min | 300cuts/min | 300cuts/min | 300cuts/min |

| 9. Max.cutting speed | 300m/min | 300m/min | 300m/min | 300m/min |

| 10. Requirement of the air pressure | 0.8MPa | 0.8MPa | 0.8MPa | 0.8MPa |

| 11. Voltage | AC380V/220Vx50Hz | AC380V/220Vx50Hz | AC380V/220Vx50Hz | AC380V/220Vx50Hz |

| 12. Total power: | 29KW | 29KW | 42KW | 29KW |

| 13. Accuracy of the roller paper sheet | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting. (cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting. (cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting.(cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting.(cutting one paper roll, the cutting length is right ) |

| 14. Output | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process |

CHM-1400 Specifications:

Machine Model: CHM1400 single sheeter machine

Top Tool Apron:

We use an advanced cutting method that reduces noise and load while extending the life of the knife.

Bottom Tool Apron:

The tool apron is cast and then processed for stability.

Main Driving Roller:

The roller has a grainy surface and is air-pressure controlled to grip the paper firmly.

Anti-static Bar Principle:

The anti-static bar eliminates static electricity from the sheets, preventing them from sticking together.

Conveyor Unit:

This unit horizontally conveys the paper in multiple stages, making it easy to count and pile the sheets efficiently (with high-efficiency dust collection equipment).

Piling Paper Stand:

An electric piling stand automatically lowers when the paper reaches a certain height.

Auto Jogger System:

A dynamic jogger system adjusts the front and sides, with an adjustable tailgate.

Optional Configurations:

Our Service:

We offer comprehensive services to ensure your satisfaction.

SMH Machinery, a leading paper sheeter manufacturer in China, specializes in producing high-quality paper sheeter machines. Our precise cutting and online packaging capabilities ensure efficient production to meet our customers’ needs. We optimize every detail of our cutting equipment to guarantee quality. With complete certifications, we offer assurance of quality.

Paper sheeter manufacturer in China

Looking for a high-efficiency paper sheeter or paper cutter to upgrade your production line? Our advanced paper sheeter machine is all about precise paper cutting. It gives you smooth and clean sheets every single time. Whether you need a full-scale paper machine setup or just a compact paper cut machine for specific tasks, we’ve got something that’ll work perfectly for you. With our reliable equipment, you can definitely boost your productivity!