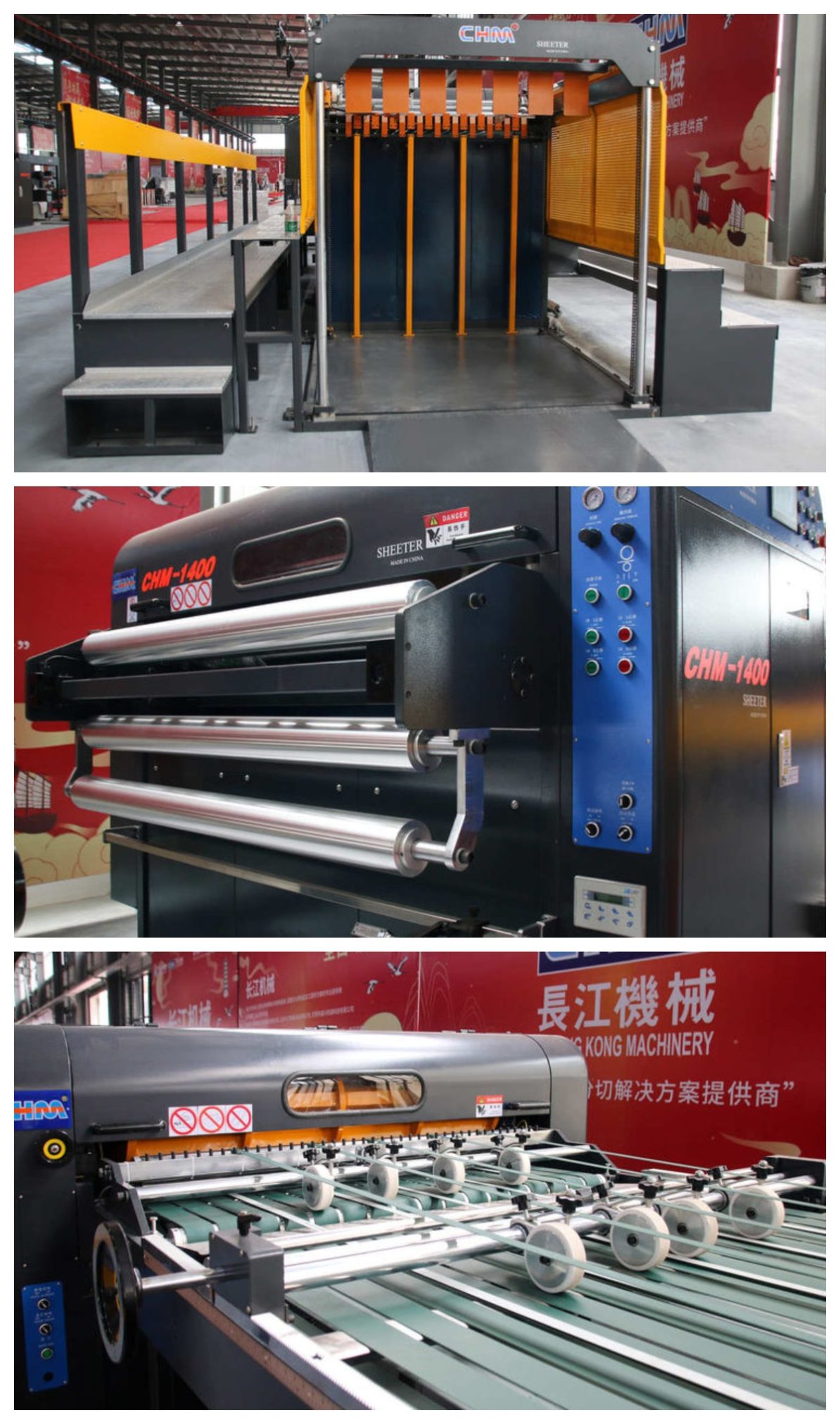

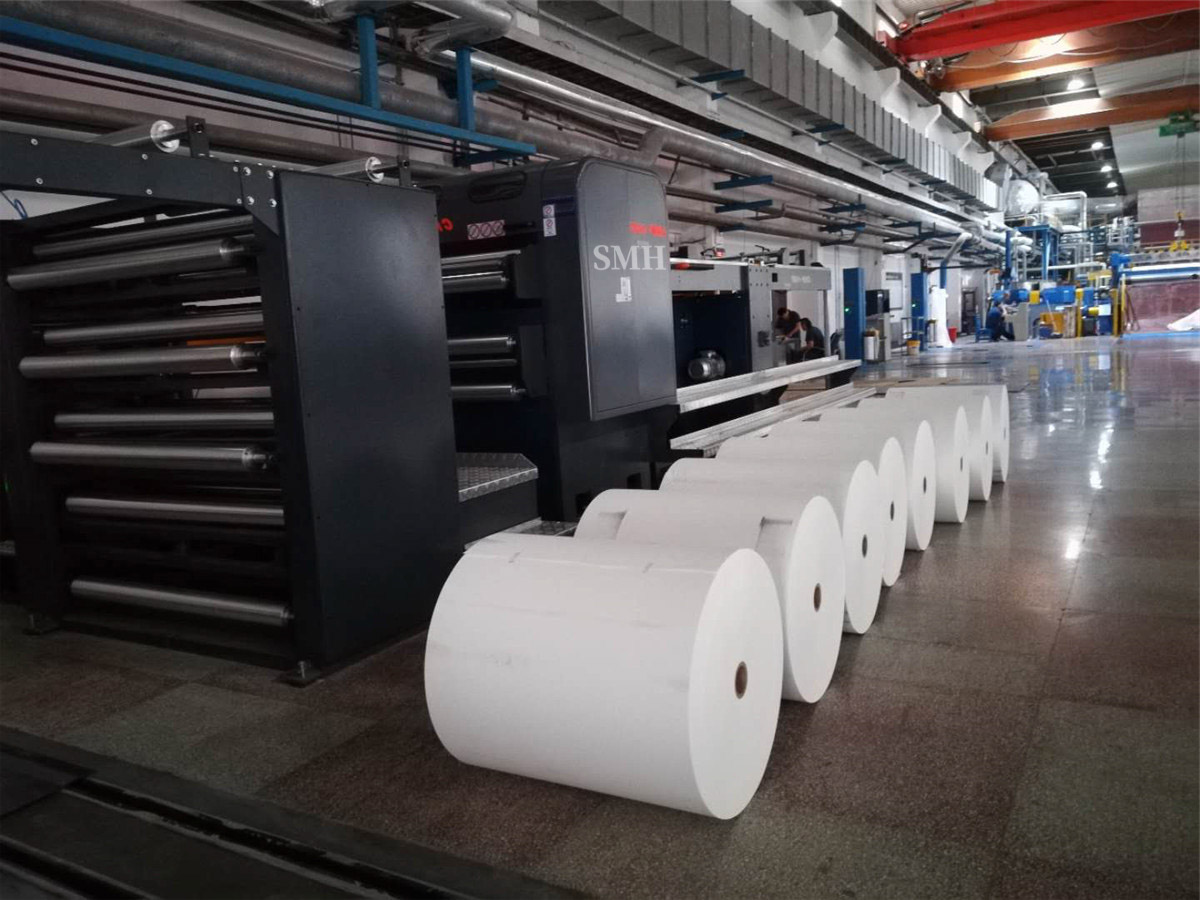

Our paper cutter is in the exhibition hall, accepting customers’ visits. SMH’s paper cutters have met many customers’ high standards for slitting quality. The generation of paper fuzz and paper powder has been reduced.

Our paper cutter is in the exhibition hall, accepting customers’ visits. SMH’s paper cutters have met many customers’ high standards for slitting quality. The generation of paper fuzz and paper powder has been reduced.

The reasons why SMH has a good reputation and high quality in the field of sheeter machine (web paper cross-cutting machine) are mainly as follows:

⸻

✅ 1. Focus on cross-cutting field, with deep technical accumulation

SMH has long been dedicated to the research and development of paper processing equipment, especially cross-cutting equipment, and has over 20 years of industry experience. Its core technologies have been continuously optimized and a mature product system has been formed. Especially in aspects such as double-knife synchronous paper cutting technology and servo control systems, it leads the industry level.

⸻

✅ 2. High precision control system

The cross-cutting machines of SMH generally adopt the German Siemens PLC control system and the Japanese Yaskawa servo motor to ensure:

The error of paper cutting length can be controlled within ±0.2mm

The synchronization speed is smoothly controlled to avoid paper pulling and paper breaking

Automatically adjust the paper cutting length and speed to meet the requirements of different materials and orders

⸻

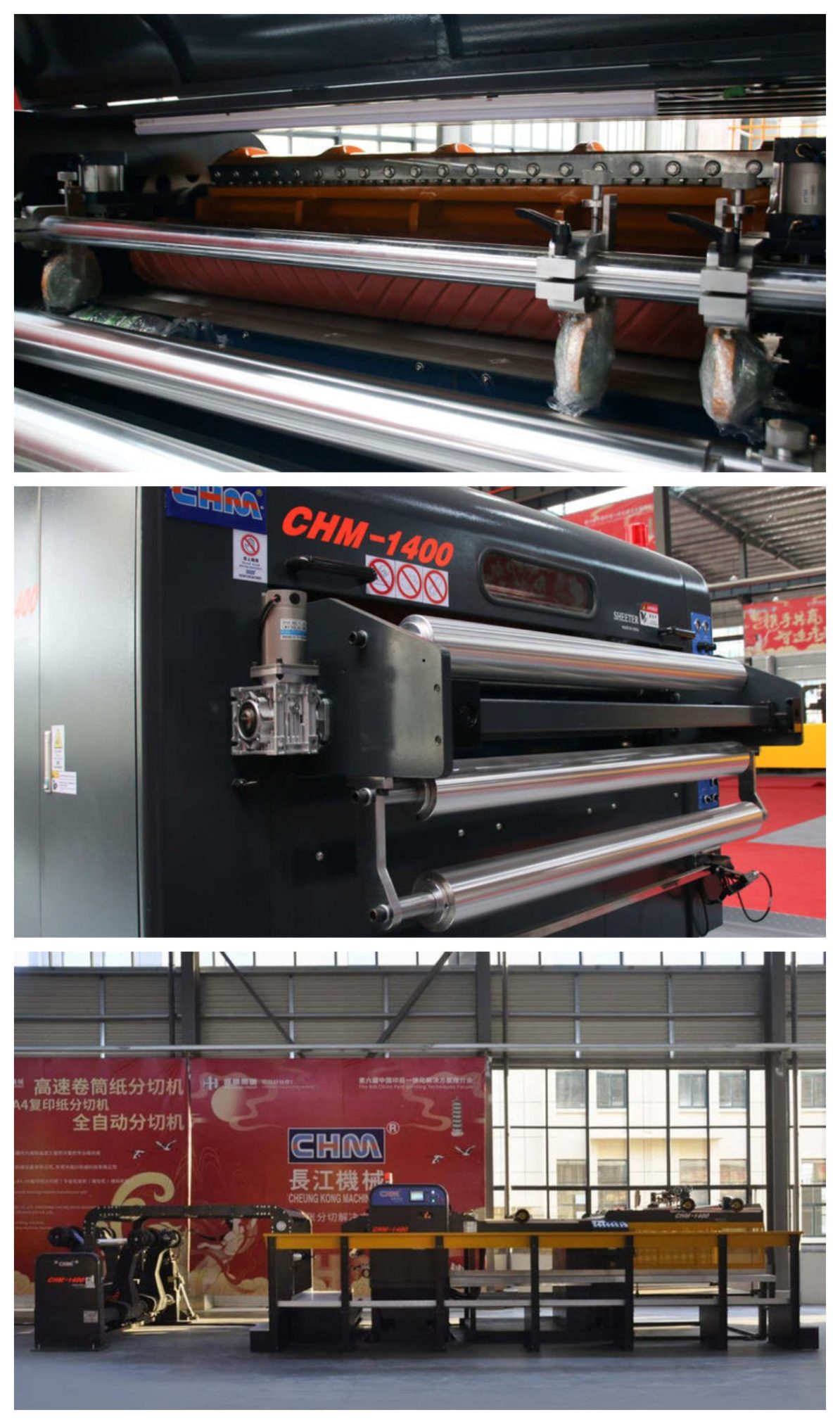

✅ 3. Double-blade structure, high efficiency, beautiful cut

SMH ‘s popular models such as the SMH-1400/1700/1900 series, which use the twin rotary system (knives), have the following advantages:

The edges of the paper cut are smooth and free of burrs

It has good stability when cutting paper at high speed continuously (up to 300 meters per minute).

It is particularly suitable for processing high-end papers such as coated paper and white card paper

⸻

✅ 4. High degree of automation, less labor

SMH focuses on intelligence and automation in product design, such as:

⸻

✅ 5. International procurement of key components, quality guaranteed

Key component brand/country

PLC controller Siemens (Germany)

Servo drive Yaskawa (Japan)

Cutting tool steel: High-strength alloy steel from Japan or Germany

Bearings and guide rails NSK (Japan), HIWIN (Taiwan)

These high-quality components ensure the long-term stable operation of the machine and reduce the maintenance rate.

⸻

✅ 6. Improve after-sales service and global layout

SMH has established sales and service networks in many countries around the world, such as India, Indonesia, Vietnam, Russia, Turkey, etc., and possesses:

This is particularly important for export customers.

⸻

📌 Summary:

The reason why SMH’s sheeter machines is of good quality is that it integrates high-end configuration, precise control, excellent structural design and a perfect after-sales system. It is not only suitable for paper processing plants and large-scale printing enterprises, but also widely used in high-demand customer groups such as packaging paper mills and label factories.

For a lot of paper companies, dealing with rough edges on cut paper is a real pain. When we need to cut a big stack of paper, we usually just pile it all up together because of time and size constraints, hoping to get the job done in one go. But when there’s too much paper stacked up, it often leads to misalignment or shifting during the cutting process. This causes uneven cuts on each sheet, and because the force isn’t applied evenly, the edges end up being rough.

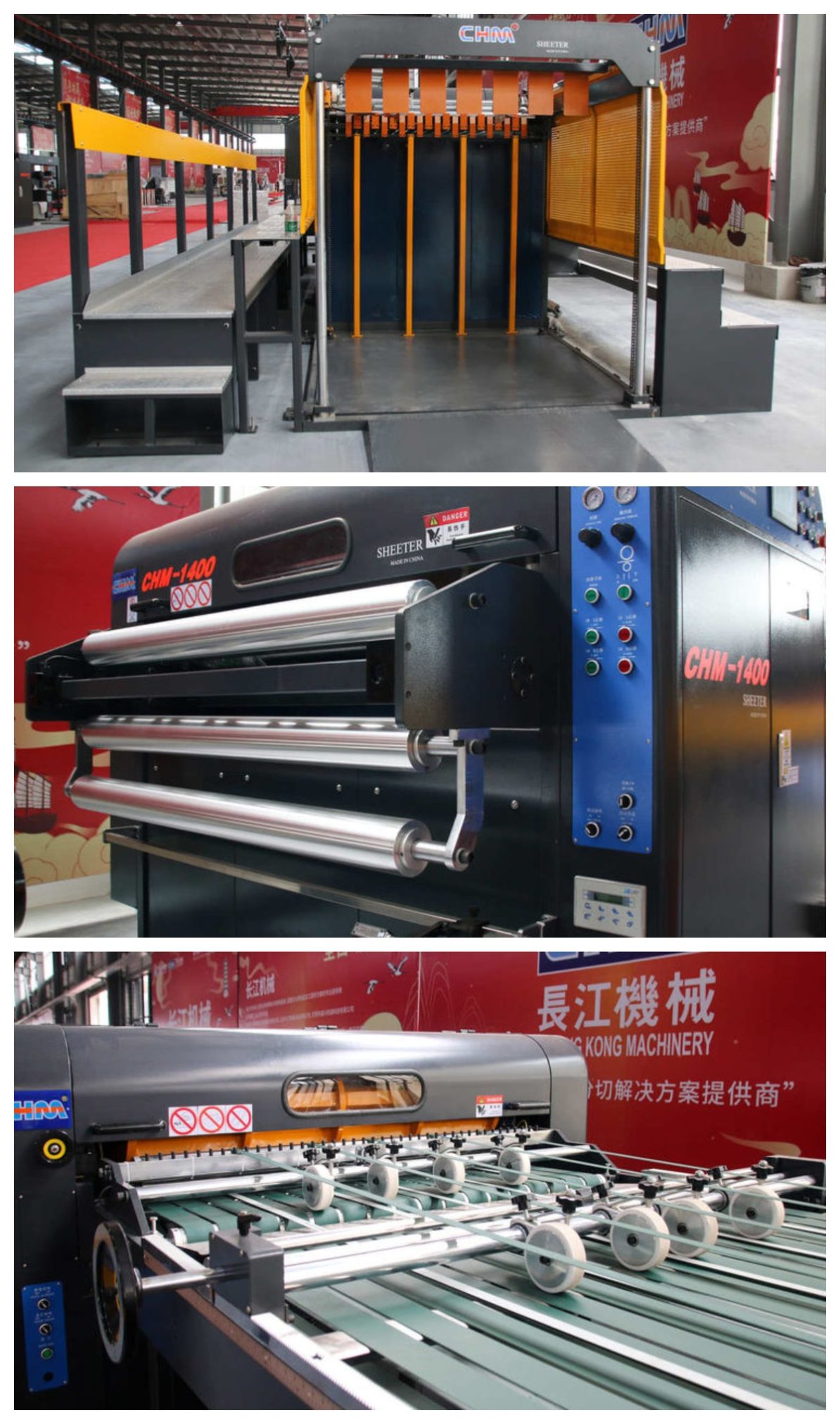

To tackle this issue, SMH has come up with a double-knife slitting machine after years of development. It uses two rotating knife shafts at the top and bottom for cutting, which ensures high precision. After high-speed slitting, the edges of the paper are smooth and clean, with no burrs, light spots, or indentations. This completely solves the problem of paper fibers and allows the slitted products to be printed directly without any extra processing.

So, how exactly does SMH’s double-knife system fix the issue of paper fibers? The double knives from Changjiang Machinery use a trailing slitting design with advanced technology in the knife heads. While waiting for the paper to be fed in, the knife heads stay still. Only when the paper reaches the set size does the upper and lower knife heads suddenly accelerate to the edge and slit the paper simultaneously. This guarantees that the edges are flat and clean, leaving no paper fibers behind. Plus, the edge and corner adjustments are already fixed by the knife head before the machine leaves the factory. During slitting, the squareness of the flat paper is ensured without needing further adjustments.

Here’s a bit more about the equipment:

SMH has always been highly regarded by customers both domestically and internationally. Its market share keeps growing, earning trust and recognition from a wide range of customers. This success is due not only to its perfect quality management system and pursuit of excellence but also to its continuous R&D efforts and spirit of innovation.

First-Class Service:

When SMH delivers a double-drum slitting machine to you, they’ll also train your operators until they’re fully confident in using the machine and can start cutting paper independently. If you ever need to train new operators, SMH regularly holds paper-cutting engineer training camps—feel free to join! Besides these services, Changjiang Machinery offers additional unique services:

The Technical Support Center (TSC) provides 24/7 service, including:

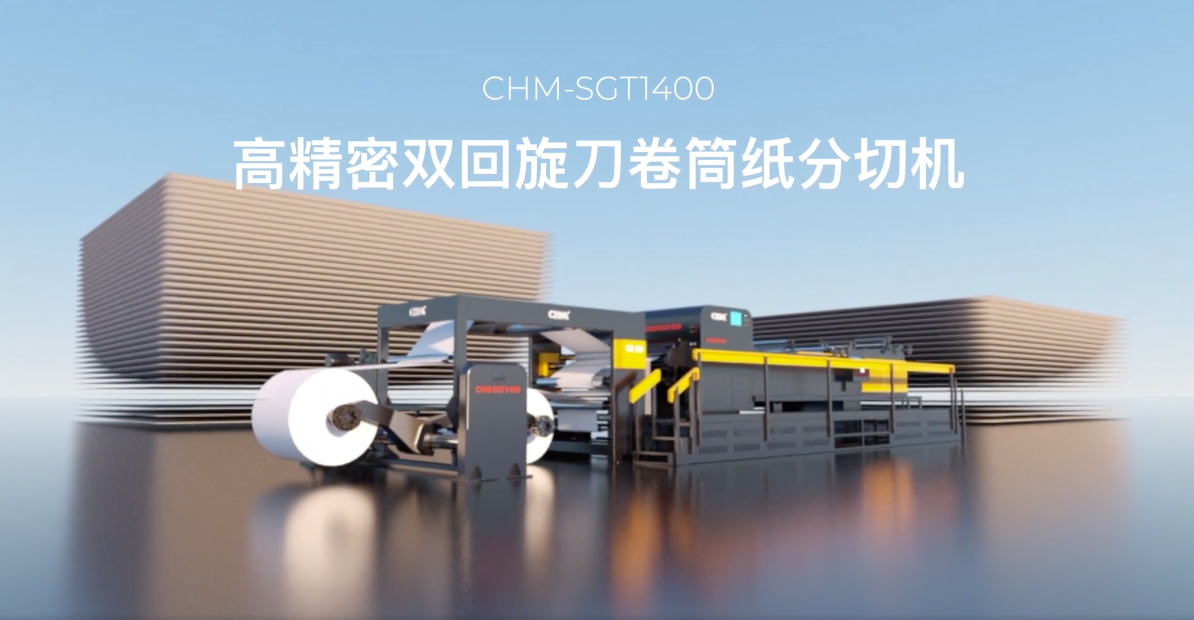

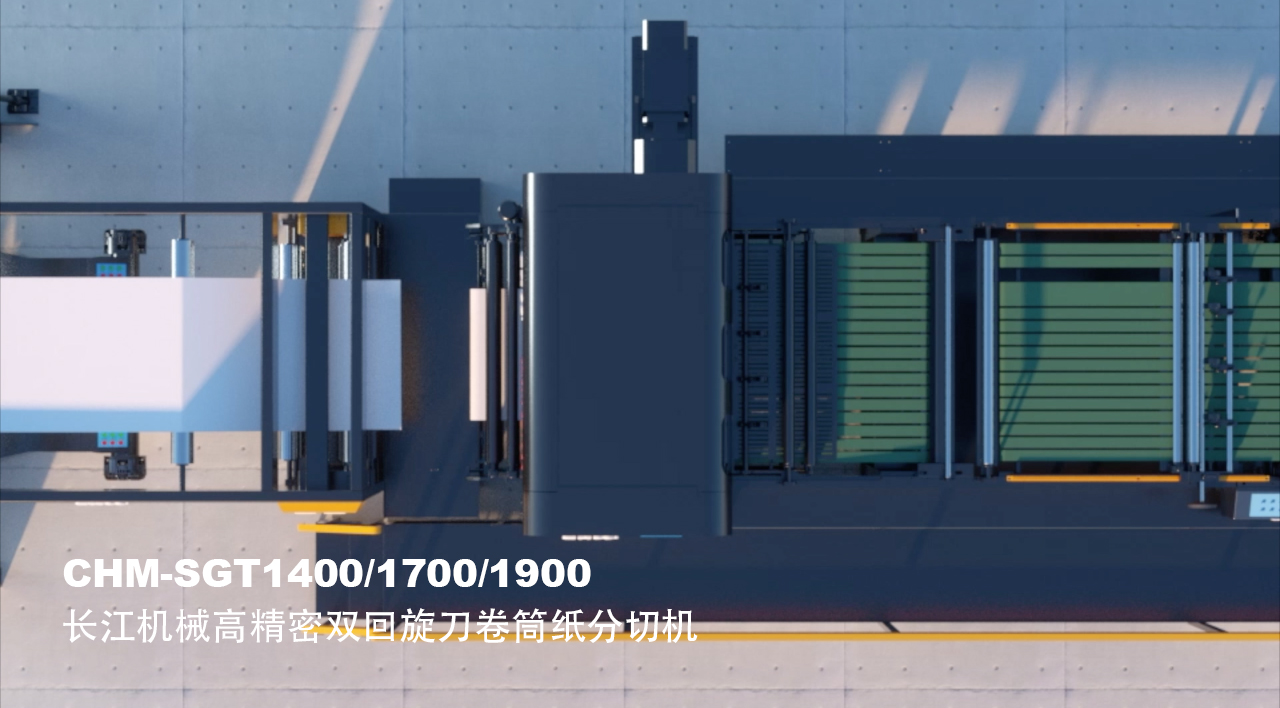

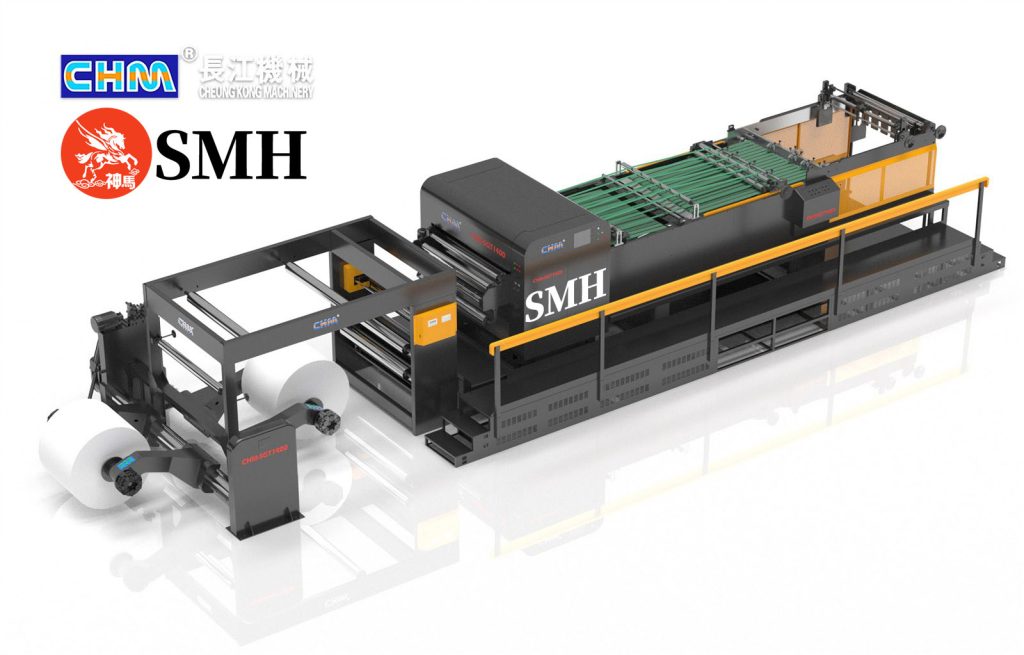

SMH Double Rotary Paper Sheeter

Different Machine Model

SMH-Double Rotary Paper Sheeter

Watch the video of CHM-SGT1400/1700/1900 Sheeter SMHSeries

| Model | CHM-SGT1400 | CHM-SGT1700 | CHM-SGT1900 |

| 1. Type of cutting | Top blade and bottom blade rotary | Top blade and bottom blade rotary | Top blade and bottom blade rotary |

| 2. weight of paper | 200-1000 GSM | 200-1000 GSM | 200-1000 GSM |

| 3.reel diameter | Max 1800mm(71″) | Max 1800mm(71″) | Max 1800mm(71″) |

| 4. Finished width | Max 1400mm(55″) | Max 1700mm(66.9″) | Max 1900mm(74.8″) |

| 5. Finished sheet-Length | Min.450-Max.1650 mm | Min.450-Max.1650 mm | Min.450-Max.1650 mm |

| 6. Num. of rolls cutting | 2 rolls | 2 rolls | 2 rolls |

| 7. Cutting accuracy | ±0.5mm | ±0.5mm | ±0.5mm |

| 8. Max. speed of cutting | 300cuts/min | 300cuts/min | 300cuts/min |

| 9. Max. cutting speed | 300m/min | 300m/min | 300m/min |

| 10. Requirement of the air pressure | 0.8MPa | 0.8MPa | 0.8MPa |

| 11. Voltage | AC380V/220Vx50Hz | AC380V/220Vx50Hz | AC380V/220Vx50Hz |

| 12. Total power: | 88KW | 88KW | 90KW |

| 13. Output | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process |

| 14. Series | SMHSeries | SMHSeries | SMHSeries |

| 15. After-Sale | 24/7 | 24/7 | 24/7 |

More information

| Place of Origin | Dongguan city,Guangdong province |

| Brand Name | CHM |

| Minimum Order Quantity | 1 set |

| Payment Terms | T/T or LC |

| Price | Negotiated |

| Delivery Time | 30 to 45 working days |

Products Description

Double rotary paper sheeter machine, high precision double rotary sheeter machine cuts clean paper, no paper wool, no spots, no indentation, can be directly fed into the printing press. High cutting accuracy. Suitable for cutting weight range is 200 to 1000 grams, especially suitable for cutting thin paper. Such as board paper, RAT paper, kraft paper and packaging paper or cardboard.

Product Display

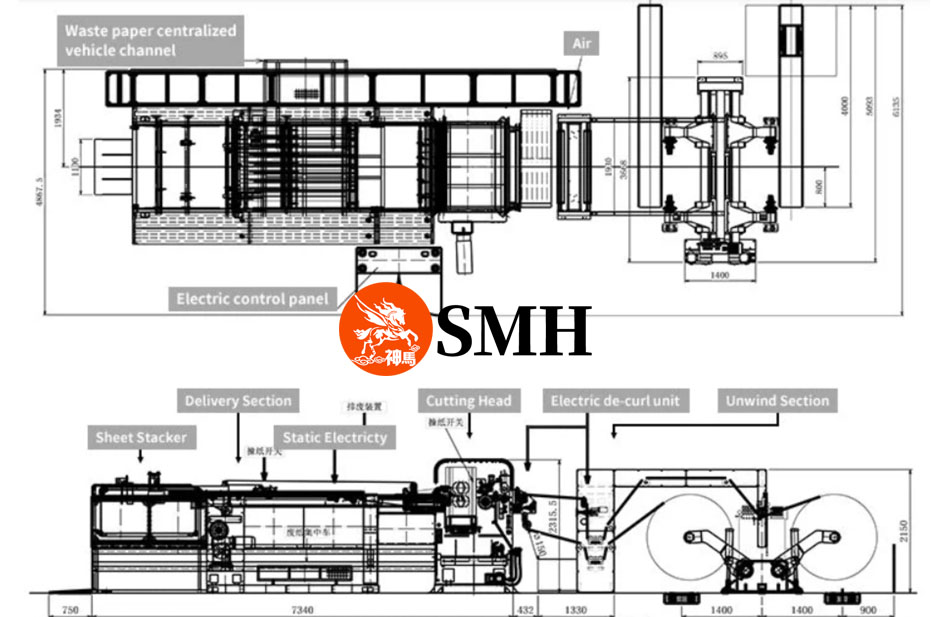

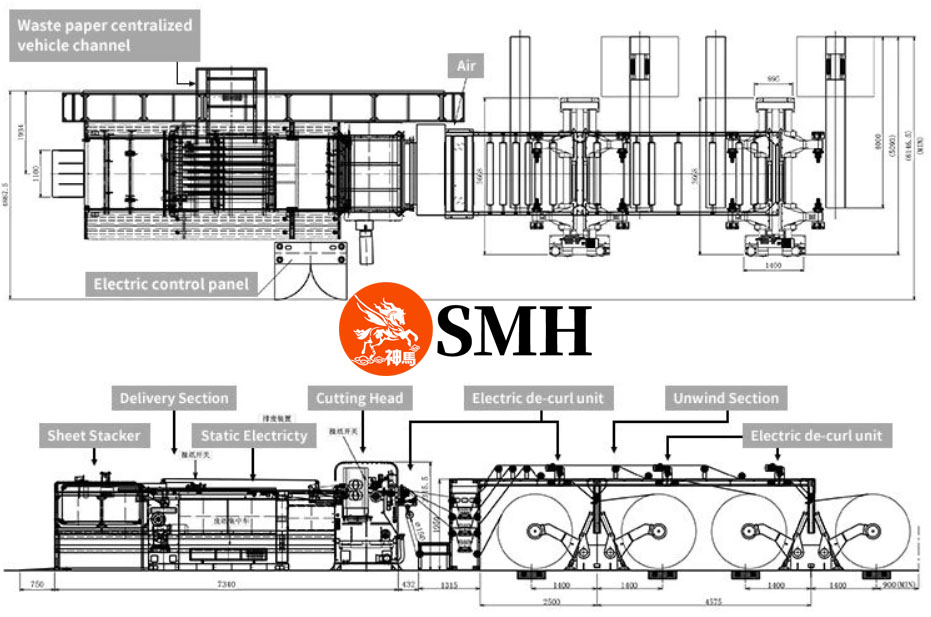

CHM Precision Paper Sheeter Machine drawing

CHM-SGT1400 Double Rotary Sheeter Machine

CHM-SGT1400II Double Rotary Sheeter Machine

Product Details

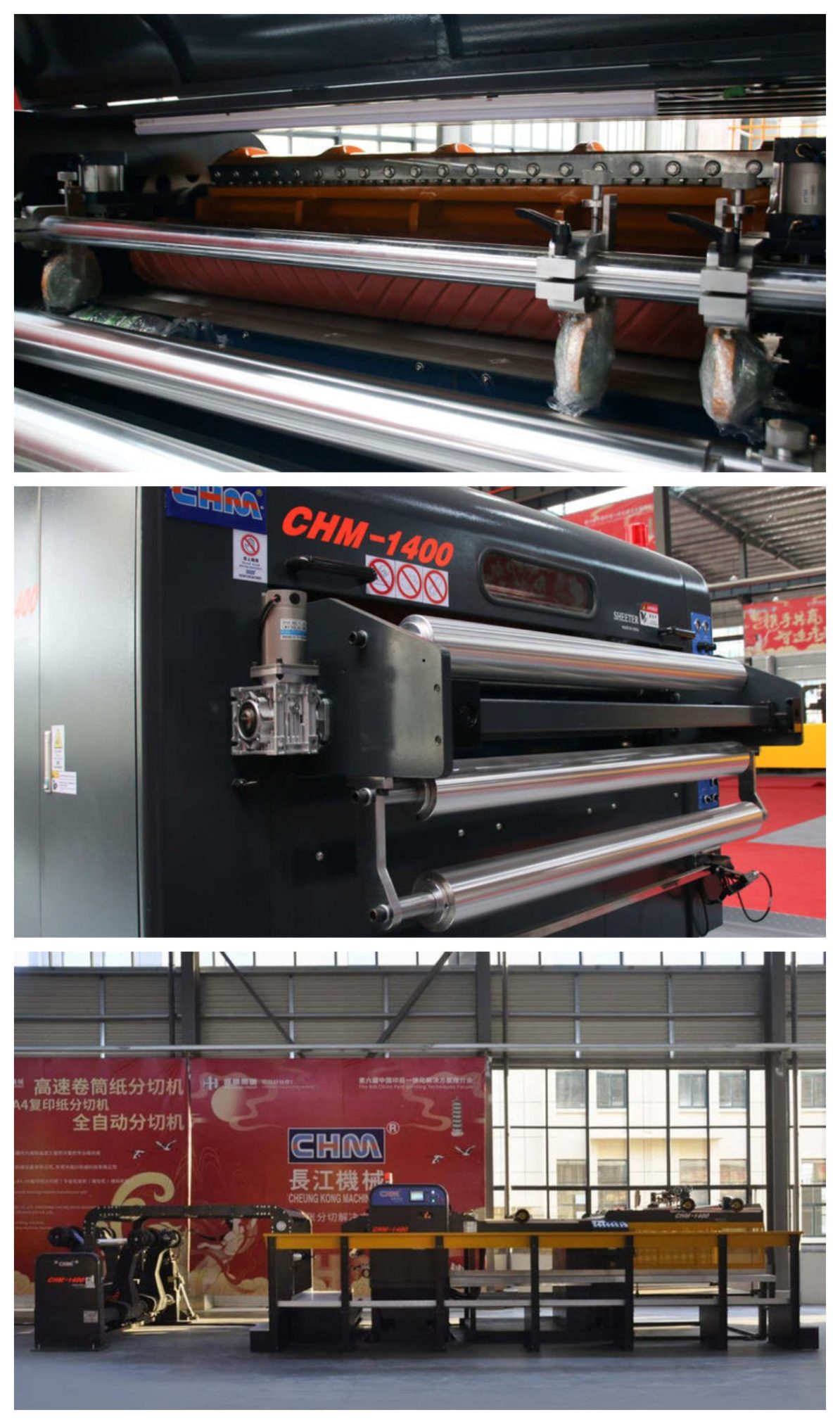

CHM Introduction

CHM, Cheung Kong Machinery (HK) Co., Ltd., the professional sheeting machine manufacturer and the leading paper sheeting solution provider in China.

Since 2004, established in Hong Kong, CHM group keeps forwarding with the idea of insists on a client-centric and innovation. CHM has becóme the leader of the paper sheeting machinery producer in China.

Owns the highest number of patent in the industrial. We are well-known as the “standard setter”. With our solid technological capabilities, we have nurtured numerous professionals in the field. And now having the highest production capabilities in China. Moreover, the international standard after-sales technical team providing state-of-the-art services to our clients, receiving all-rounded recognitions among our Chinese and global clientele,

Nowadays, CHM has become the flagship enterprise in the Chinese sheeting machinery industrial and expanding towards the international market.