描述

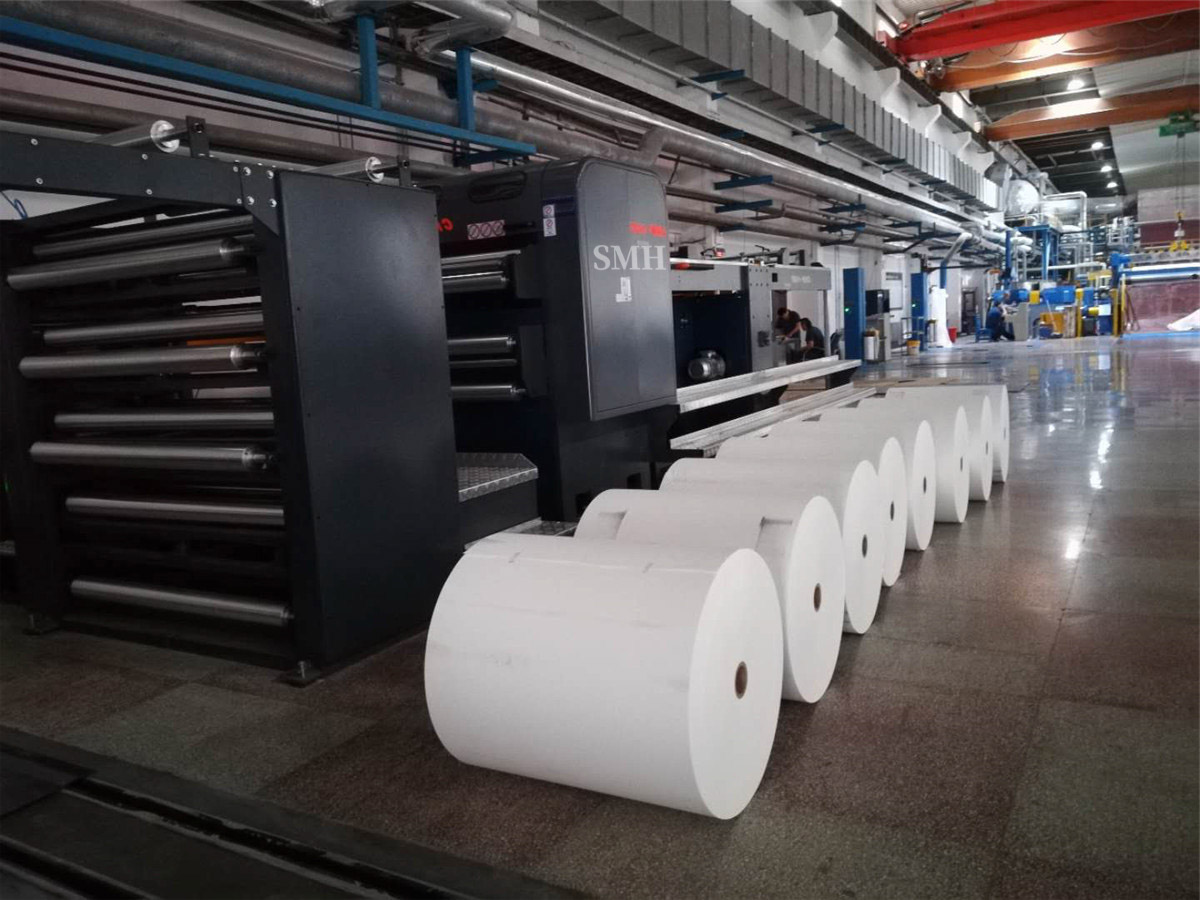

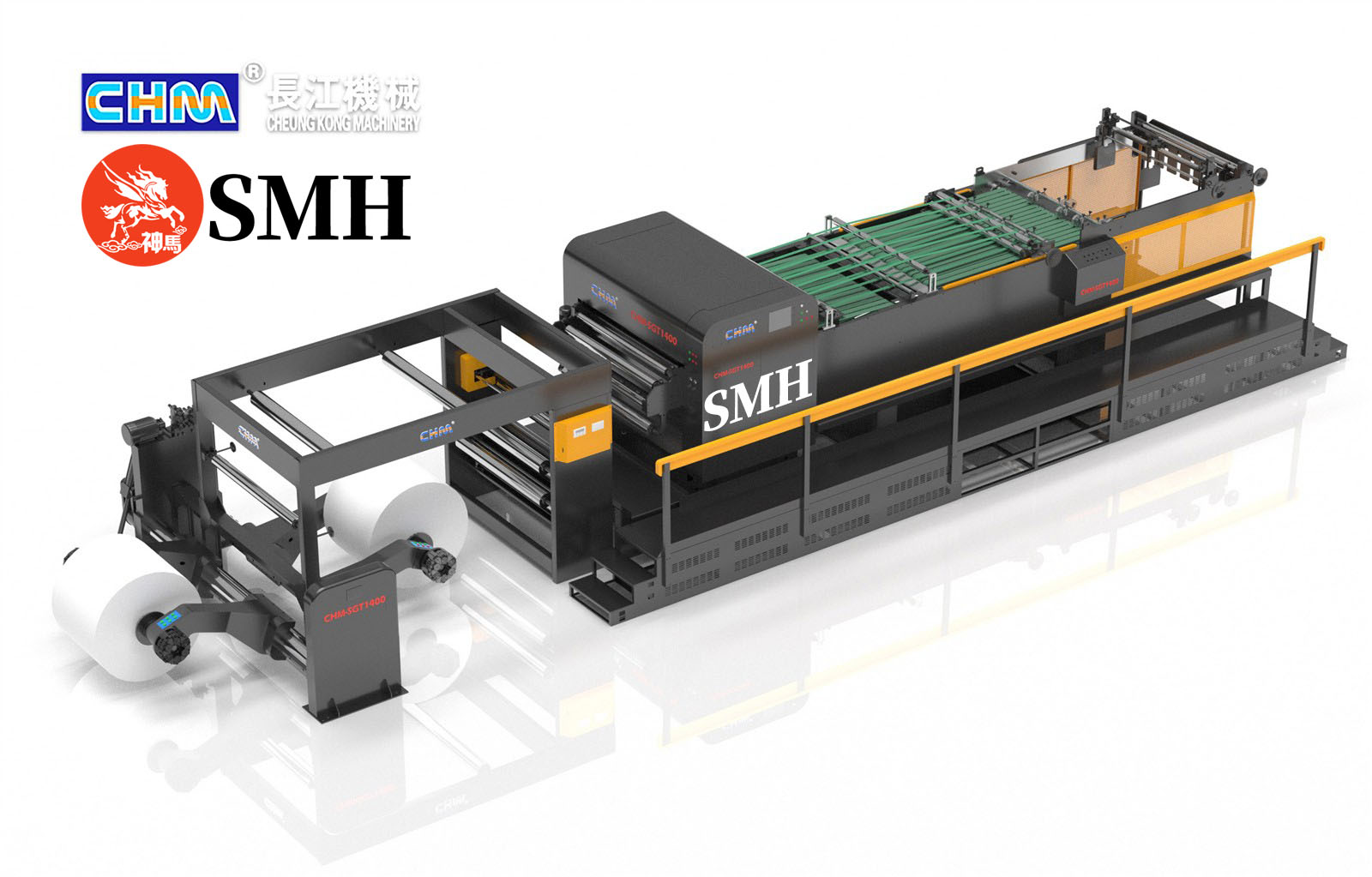

Sheeter Machine SMH Series

We’re a professional manufacturer of sheeting machines and one of the leading paper sheeting solution providers in China. Our machines are mainly used for paper sheeting in paper mills, printing houses, and other similar industries. The process includes: unwinding, cutting, conveying, and collecting. It’s really easy to operate!Process flow: Unwinding → Loading → Transverse Cutting → Conveying → Collecting; primarily designed for paper products.Product Introduction

technical parameter

SMH Series

| Model | CHM-1400 | CHM-1700 | CHM-1900 | CHM-1100 |

| 1. Type of cutting | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed |

| 2. weight of paper | 60-550 GSM | 60-550 GSM | 60-550 GSM | 60-550 GSM |

| 3..reel diameter | Max 1800mm (71″) | Max 1800mm (71″) | Max 1800mm(71″) | Max 1800mm(71″) |

| 4. Finished width | Max 1400mm (55″) | Max 1700mm (66.9″) | Max 1900mm(74.8″) | Max 1100mm(74.8″) |

| 5. Finished sheet-Length | Min.450-Max.1650 mm | Min.450-Max.1650 mm | Min.450-Max.1650 mm | Min.450-Max.1650 mm |

| 6. Num.of rolls cutting | 2 rolls | 2 rolls | 2 rolls | 2 rolls |

| 7. Cutting accuracy | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) | ±0.5mm(L<1000mm)±0.1% (L≥1000mm) |

| 8. Max.speed of cutting | 300cuts/min | 300cuts/min | 300cuts/min | 300cuts/min |

| 9. Max.cutting speed | 300m/min | 300m/min | 300m/min | 300m/min |

| 10. Requirement of the air pressure | 0.8MPa | 0.8MPa | 0.8MPa | 0.8MPa |

| 11. Voltage | AC380V/220Vx50Hz | AC380V/220Vx50Hz | AC380V/220Vx50Hz | AC380V/220Vx50Hz |

| 12. Total power: | 29KW | 29KW | 42KW | 29KW |

| 13. Accuracy of the roller paper sheet | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting. (cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting. (cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting.(cutting one paper roll, the cutting length is right ) | ±0.5mm(L<1000mm);±0.1% (L≥1000mm)±0.1%(accelerate or decelerate).This depend on machine stable and operation when cutting.(cutting one paper roll, the cutting length is right ) |

| 14. Output | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process | The real output depend on the material, and the weight of the paper, and right operate process |

- Two rolls, width: 889mm

- Paper type: 120g double-sided coated paper

- Paper type: Black cardboard

- GSM: 380g

- Speed: 301 cuts per minute

- Size: 787×1092

- First Conveying Stage: Quickly separates the cut paper.

- Second Conveying Stage: Slowly conveys the paper in a tile-like shape, with single or linked control options.

- Auto-Cursor Tracking System (optional): Tracks and positions the cursor accurately.

- High-Speed Encoder: Calculates the cursor distance quickly and precisely.

- Cursor Function Server: Cuts color codes more accurately.

- Cursor Sensor: Detects the cursor’s color, width, and distance.

- Cursor Sensor Bracket: Positions and tracks the cursor.

- Cutter Head Reference Sensor: Collects data on the cursor distance, cutting knife, and paper-cutting pulse signals for processing.

- Pre-Sale Service: We provide product consultations and custom one-on-one slitting solutions tailored to your needs, along with technical support.

- Installation Service: We guide you through installation and handle the setup and commissioning of the machine. We also train novice operators and provide detailed instruction manuals.

- After-Sale Service: We offer remote guidance and maintenance for your machines, with a one-year warranty included.