Pile Turner

We’ve always focused on making top-notch, fully automatic pile turners while offering complete solutions for the commercial printing, pharmaceutical, printing, and packaging industries. Our machines are built to meet CE standards, keeping both safety and user convenience in mind. Each pile turner is carefully made by our team at our facility. These devices have been shipped all over the world, including places like the U.S., Australia, South Korea, and Japan.

AUTOMATIC PILE TURNER

With just one command from the operation panel, you can easily align and rotate your paper stack without any hassle.

Pile Turner in South Korea

Our pile turners are also well-established in Vietnam and available across Europe.

Aligning and Turning Your Paper Pile by One Click in Operation Panel

Pile Turner is in South Korea

Pile Turner is in Vietnam

Pile Turner is in Europe

Introduction

The fully automatic pile turner is designed to efficiently flip paper piles during double-sided printing operations. Additionally, it enables operators to swiftly change pallets, align and condition piles in a time-saving manner, eliminate ink odors, and remove dust through aeration. Pile turners are indispensable for replacing manual labor, enhancing productivity and print quality, and separating sheets to prevent misfeeds in paper handling equipment. Our machines comply with CE standards and are engineered for high operational safety and ease of use.

Functions of the Pile Turner

The pile turner serves not only as a flipping unit but also provides the following functionalities:

- Flipping the pile

- Aligning the pile

- Airing (with optional ionized air)

- Dust removal

- Separating cutting edges

- Removing spray powders

- Drying (optional)

- Eliminating ink odor

- Centering the pile

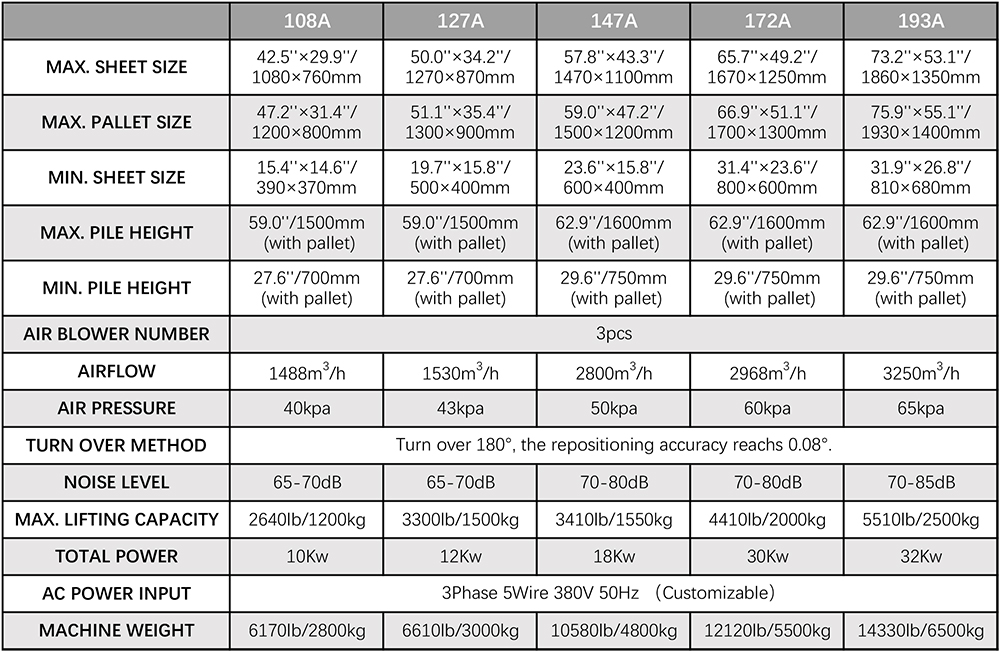

Specification

| 108A | 127A | 147A | 172A | 193A | |

| MAX. SHEET SIZE | 42.5″x29.9″/1080x760mm | 50.0″x34.2”/1270x870mm | 57.8″x43.3″/1470x1100mm | 65.7″x49.2″/1670x1250mm | 73.2″x53.1“/1860x1350mm |

| MAX. PALLET SIZE | 47.2″x31.4″/ 1200x800mm | 51.1″x35.4″/ 1300x900mm | 59.0″x47.2″/1500x1200mm | 66.9″x51.1″/ 1700x1300mm | 75.9″x55.1“/1930x1400mm |

| MIN. SHEET SIZE | 15.4”x14.6″/390x370mm | 19.7″x15.8″/500x400mm | 23.6″x15.8″/600x400mm | 31.4″x23.6″/800x600mm | 31.9″x26.8”/810x680mm |

| MAX. PILE HEIGHT | 59.0″/1500mm(with pallet) | 59.0″/1500mm(with pallet) | 62.9″/1600mm(with pallet) | 62.9″/1600mm(with pallet) | 62.9″/1600mm(with pallet) |

| MIN. PILE HEIGHT | 27.6”/700mm(with pallet) | 27.6”/700mm(with pallet) | 29.6”/750mm(with pallet) | 29.6”/750mm(with pallet) | 29.6”/750mm(with pallet |

| AIR BLOWER NUMBER | 3pcs | 3pcs | 3pcs | 3pcs | 3pcs |

| AIRFLOW | 1488m³/h | 1530m³/h | 2800m³/h | 2968m³/h | 3250m’/h |

| TURN OVER METHOD | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° | Turn over 180°,the repositioning accuracy reachs 0.08° |

| NOISE LEVEL | 65-70dB | 65-70dB | 70-80dB | 70-80dB | 70-85dB |

| MAX. LIFTING CAPACITY | 2640lb/1200kg | 3300lb/1500kg | 3410lb/1550kg | 4410lb/2000kg | 5510lb/2500kg |

| TOTAL POWER | 10Kw | 12Kw | 18Kw | 30Kw | 32Kw |

| AC POWER INPUT | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) | 3Phase 5Wre 380V 50Hz (Customizable) |

| MACHINE WEIGHT | 6170lb/2800kg | 6610lb/3000kg | 10580lb/4800kg | 12120lb/5500kg | 143301b/6500kg |

| AIR PRESSURE | 40kpa | 43kpa | 50kpa | 60kpa | 65kpa |

Here’s a quick overview:

Designed for smooth double-sided printing, our fully automatic pile turner helps rotate paper stacks efficiently. It lets operators switch pallets quickly, align stacks properly, and condition them effectively—all while saving time. Plus, it removes dust through aeration, gets rid of ink odors, and ensures sheets separate smoothly to avoid misfeeds in paper handling systems. Our equipment meets CE standards and is designed with safety and ease of use as priorities.