One must cultivate the spirit of a craftsman, moving from “craftsmanship” to “craft soul”. With “Made in China” becoming increasingly proficient, it can then evolve into “Made with Excellence in China”.

“Chinese precision manufacturing” has stabilized. There is no need to worry about “Chinese creation” not existing. We must not let “Made in China” fail before it is fully developed. We need to take it step by step. Handicraft work is the foundation and prerequisite for automation.

A rigorous attitude nurtures a professional spirit.

For SMH, the production of any cutting machine involves thousands of procedures. From the strict selection of raw materials to the efficient assembly in the production workshop, and then to the rigorous testing before leaving the factory, the entire process takes about 20 days. No matter which step is involved, no shortcuts can be taken; otherwise, the entire machine will be ruined.

Any non-compliant products must not be allowed to leave the factory of SMH Machinery!

A front-line worker in the workshop reported that from the top management (such as the team leader, production manager, and quality manager) down to the lower levels, the inspection of the products was extremely strict. Any product that did not match the drawings had to be reworked and refined. However, this strict attitude also fostered the professional spirit of the workers, so the employees did not complain.

From semi-automatic production to fully automatic production

From the first industrial revolution led by steam engines, to the second industrial revolution driven by electricity, and then to the third industrial revolution powered by computers, each time it was based on the release of human resources and aimed at quantitatively enhancing productivity. In the 21st century, the new human beings are moving towards the intelligent new era.

Industrial production integrates innovation and technology. Fully automated mechanical production is not an impossible dream.

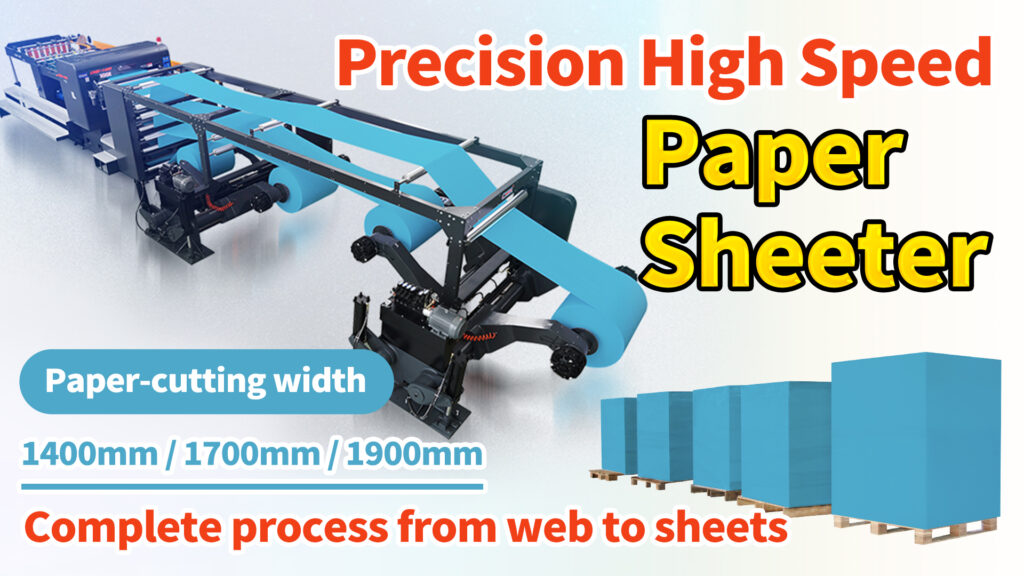

The “A4 Copy Paper Cutting Machine Production Line” produced by SMH Machinery has achieved full automation production! The PLC system independently controls the equipment to automatically complete the processes of paper feeding, collection, counting, packaging, and boxing.

It has greatly liberated human resources. Achieving this effect is attributed to the forward-thinking vision and persistent dedication of the scientific researchers at Changjiang Machinery over the years.

An innovative small step, a huge leap forward for the times. The success of the A4 copy paper production line is just one example. More outstanding inventions made in China are gradually driving the development of this country and the progress of this era.

Today, the spirit of craftsmanship not only embodies the concept and pursuit of meticulously crafting and meticulously producing products, but also requires continuous absorption of the latest technologies to create new achievements.