“Previously, we wasted 5% of raw paper during cutting—thousands of dollars lost annually.”

This is what Mr. Li, a factory owner in Guangdong, China, shared. His plant used outdated machines that were slow, inaccurate, and prone to jams. After switching to a high-speed roll paper sheeter, everything improved.

Here’s how they turned losses into profits:

- Cutting accuracy: ±0.3mm precision, no jams or skewed stacks.

- Fast operation: Up to 400 sheets/min, line speed up to 320m/min.

- Smart control: Preset sizes for instant switching.

- Stable quality: Key parts made from imported steel; operates 12 hours fault-free.

Real Case Study:

Mr. Li’s factory processes 15 tons of roll paper daily. After upgrading to SMH’s sheeter:

- Saved $1,000/month in labor costs.

- Reduced waste from 5% to under 1%.

- Increased repeat orders by 23%.

“Now, my workers just push a button. The machine does the rest,” said Mr. Li.

Interested in upgrading? Check specs here: www.smhmachine.com.

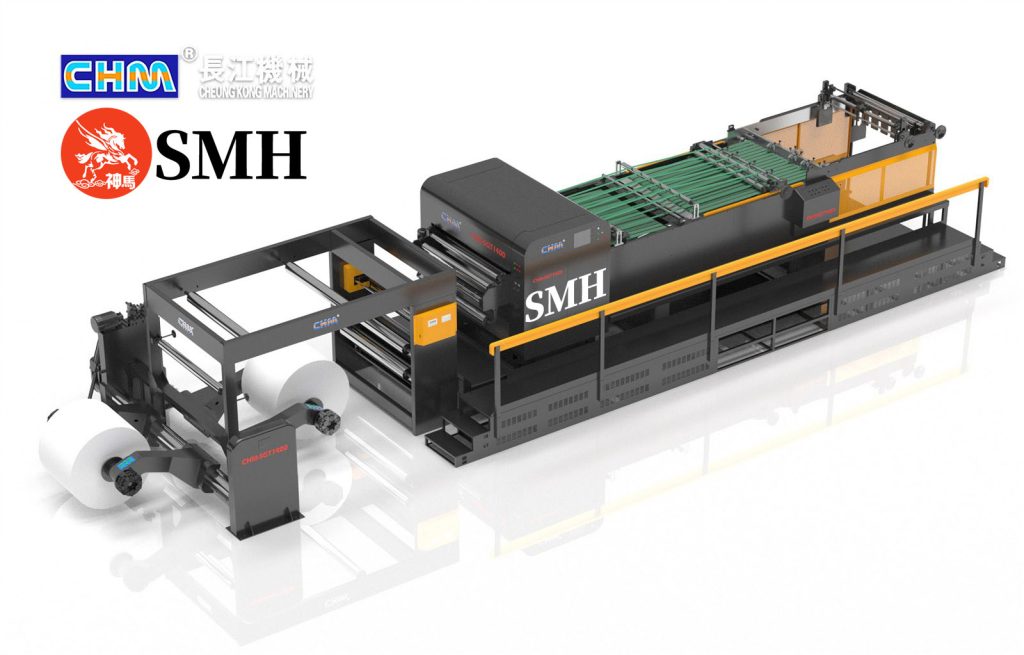

Why Printing Plants from Vietnam to Mexico Trust This Roll Paper Sheeter from China

The global printing industry faces rising labor costs, paper price hikes, and tight deadlines. One mistake in cutting can mean lost contracts. That’s why companies worldwide choose SMH’s high-speed roll paper sheeter—designed in China, exported globally.

Feedback from Global Clients:

- Vietnam (Ho Chi Minh): 30% productivity gain over manual sheeting.

- Mexico City: Significant waste reduction for offset-grade papers.

- Istanbul, Turkey: 90%+ machine utilization with ERP integration.

Key Technical Highlights:

- Working width: 500–1500mm.

- Max speed: 320 meters/minute.

- Features: Automatic stacking, tension control, web guiding.

- Certification: CE-approved, ready for global shipment.

- Support: Remote installation and on-site assistance.

For commercial printers or distributors, efficiency starts with the sheeter. Visit www.smhmachine.com for specs, videos, and quotes.