SHM folding machines are rapidly expanding their global presence.

From Asia (South Korea, Vietnam) to Europe (Russia), Africa (Algeria), and the Americas (Mexico), SHM folding machines are rapidly expanding their global presence. A new batch of machines is ready for shipment to seven countries—South Korea, Russia, Vietnam, Indonesia, Turkey, Algeria, and Mexico—boosting efficiency in local factories worldwide.

- Targeting Three Key Industries with Precision

SMH folding machines are custom-designed to solve the specific challenges of the printing sector, focusing on three core industries:

- Pharmaceuticals: Delivering high-precision folding for drug instructions and packaging inserts, meeting strict industry standards.

- Cosmetics: Handling varied materials like brochures and catalogs to create attractive, high-quality folds that enhance brand packaging.

- Printing: Supporting large-volume, multi-format folding with a balance of speed and accuracy to streamline post-printing production.

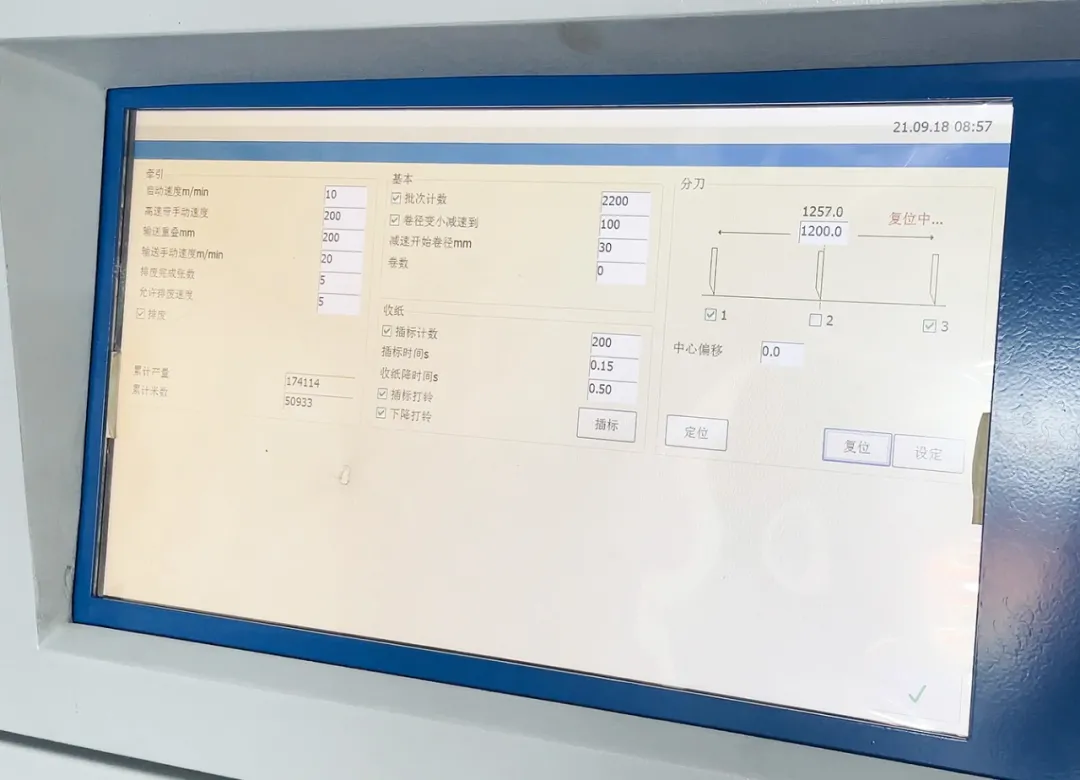

- Over 30 Patents Ensure Reliability and Quality

Equipped with more than 30 patents covering critical elements such as structure, transmission, and control systems, SMH folding machines combine advanced technology with practical benefits. These innovations guarantee stable operation, low failure rates, and reliable performance, providing customers worldwide with confidence and peace of mind.

For overseas factories, SMH folding machines offer more than just “completing folds”—they optimize the entire production process:

- Increased Efficiency: Automation minimizes manual labor, significantly speeding up folding and meeting the demands of large-scale manufacturing.

- Cost Reduction: Reliable performance lowers scrap rates and labor expenses, helping factories control overall production costs.

- Driving Modernization: As a highly efficient automated solution, SMH folding machines enable traditional factories to move away from outdated manual work and equipment, advancing toward modern production methods.

With a growing global presence, SMH folding machines continue to expand their reach. Moving forward, we remain committed to innovation and customer needs, delivering higher-quality folding equipment and solutions to factories worldwide, and serving as a trusted partner in global manufacturing upgrades.